SIGNAL INPUT RANGE SELECTION

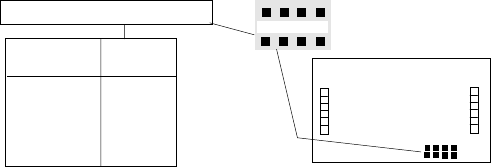

Set the jumpers to the position indicated in Table 5 for each range. The jumpers are located

on the "MP" input board. See Fig. 8.

If the signal input range is modified, follow the adjustment and calibration procedure.

FREQUENCY OUTPUT RANGE SELECTION

PULSES PER HOUR

Table 3 indicates all the standard available ranges for these models when the frequency output

must be in pulses per hour.

Set the jumpers and solder pads to the position indicated in Table 3. The jumpers are located on

the "MS-55" output module.

If the frequency output range is modified follow the adjustment and calibration procedure for each

model.

0 to 4395/8790 B, A & 1

0 to 2197/4395 C & 1

0 to 1099/2197 C, A & 1

0 to 549/1099 C, B & 1

0 to 275/549 C, B, A & 1

0 to 137/275 D & 1

0 to 68.7/137 D, A & 1

0 to 34.3/68.7 D, B & 1

0 to 17.2/34.3 D, B, A & 1

0 to 8.58/17.2 D, C & 1

0 to 4.29/8.58 D, C, A & 1

0 to 2.15/4.29 D, C, B & 1

0 to 1.07/2.15 D, C, B, A & 1

TABLE 3

The frequency output for each range is indicated : 0 to 4395/8790 for example.

This means that the minimum frequency output is 4395 Hz. and the maximum frequency output

is 8790 Hz. Any frequency within the low and high value, can be obtained using the trimmer P3

located on the "MS-55" output module.

50 % of the full cycle,

when solder pad 5, is closed.

100 mS.

when solder pad 5, is

opened.

D C B A

JUMPERS

on components

side. Snap-on type

RANGE SELECTION

0 to 100 mV A

0 to 1 V ------

0 to 10 V ------

0 to 100 V D

0 to 650 V B

INPUT CLOSE

RANGE JUMPER

FIG.8

TABLE 5

"MP" Input

board

Components

side

ADJUSTMENT AND CALIBRATION PROCEDURE

1. When input and output signal values are determined, remove the conditioner case. (Fig. 1).

2. Check on the "MA" module, if the selected power supply is correct. (Table 1).

3. Select on the input board the desired Voltage range, according to Table 5.

Caution : Do not confuse the jumpers on the "MP" board with the jumpers on the "ME" module,

(all of the jumpers on the "ME" board must be opened).

Close on "MS-55" output module, jumper E & solder pad 1, and open the jumpers A, B, C &

D and solder pads 2 & 5, according to Tables 2 and 3.

4. Connect the calibrator to the conditioner terminals : 4 and 6 for signal > 1 V.

: 5 and 6 for signal < 1 V.

5. Connect a digital voltmeter to the jumper "J4" located on the "MS-55 output module.

6. Power up the signal conditioner with the appropriate power supply.

7. Adjust the calibrator until it generates the low signal level.

8. Check the voltmeter reading is 0. If not, turn the trimmer P1, located on the "ME" input module,

until the reading of the voltmeter is 0.

9. Adjust the calibrator until it generates the high signal level.

10. Check the voltmeter reading is 10.0 V. If not, turn the trimmer P2, located on the "ME" input

module, until the reading of the voltmeter is 10.0 V.

11. Repeat steps 7 thru 10, until the two values are correct.

12. Connect a digital frequency meter, to the signal output terminals 11 and 12. The reading must

be between 2500/5000 Hz.

13. Select on the "MS-55" output module, the corresponding jumpers, according to Tables 2 & 3.

14. Adjust the calibrator until it generates the high signal level and turn the SPAN trimmer (P3),

located on the "MS-55" output module, until the frequency meter shows the desired output

frequency.

15. Disconnect the conditioner and the instruments used and reinsert into the case.

CLOSE JUMPERS/

AND SOLDER PADS

PULSES / HOUR

PULSE WIDTH

10

7