27

MODEL 396P and 396PVP SECTION 7.0

DIAGNOSTICS AND TROUBLESHOOTING

SECTION 7.0

DIAGNOSTICS AND TROUBLESHOOTING

7.1 MODEL 54e/81/3081/4081/5081/Xmt DIAGNOSTICS AND TROUBLESHOOTING

The Model 54 Analyzer and Models 81 and 3081 Transmitters automatically search for fault conditions that would

cause an error in the measured pH value, as does the Model 1054B pH/ORP Analyzer to a lesser degree. Refer to

the applicable Instruction Manual for a complete description of the analyzer’s fault conditions.

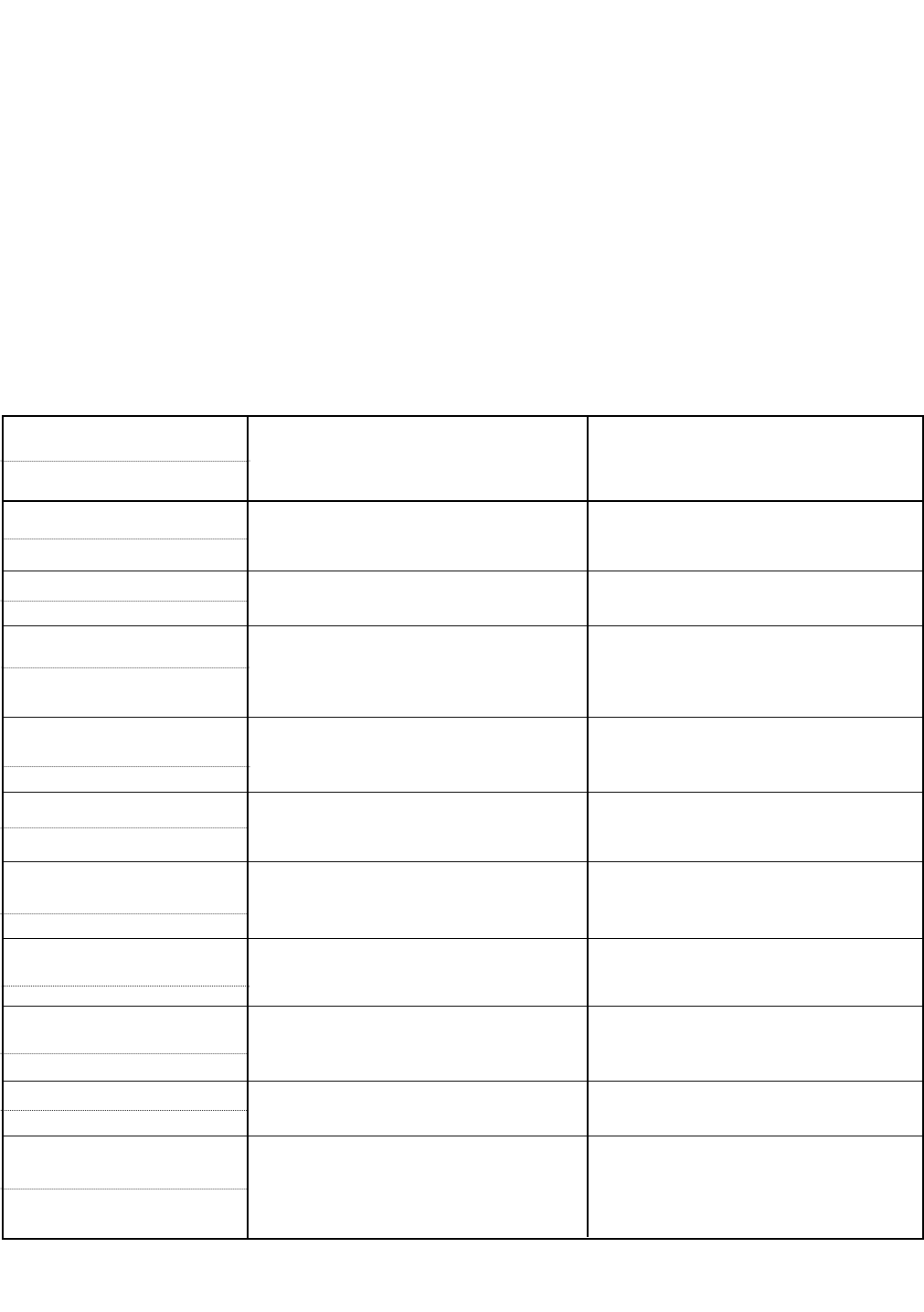

Table 7-1, below, lists the Model 54’s, 4081’s, 3081’s, and 81’s diagnostic messages that indicate a possible sen-

sor problem. A more complete description of the problem and a suggested remedy corresponding to each mes-

sage is also listed.

DIAGNOSTIC MESSAGE

54

3081/81/4081 DESCRIPTION OF PROBLEM REMEDY

“Calibration Warning” 1. Aged glass. 1. Perform buffer calibration.

2. Sensor not immersed. 2. Be sure electrode measuring tip is in

/-[5ES-U1 process.

“Cracked glass failure” Broken or cracked glass. Replace sensor.

([-<<!I-5[

“High reference impede” 1. Liquid junction coated. 1. Clean sensor; replace if necessary.

2. Reference Cell gel depleted. 2. Replace sensor.

S12!I-5[ or S12!@M-SP 3. Sensor not immersed. 3. Be sure electrode measuring tip is in

process.

“Input voltage high” pH input shorted or sensor Check wiring. Replace sensor if

“Input voltage low” miswired. necessary.

“Old glass warning” 1. Glass electrode worn out. 1. Replace sensor.

2. Sensor not immersed. 2. Be sure electrode measuring tip is in

([D<<!@M-SP

process.

“Reference offset err” Reference electrode poisoned. Replace sensor.

(offline only)

<UG!1SS

“Ref voltage high” 1. Reference shorted or sensor Check wiring and installation. Replace

“Ref voltage low” miswired. sensor if necessary.

2. Sensor not immersed

“Sensor line open” 1.

Open wire between sensor and analyzer.

1. Check sensor wiring.

2. Interconnecting cable greater than 2. Relocate analyzer.

[5P1!2-5[ 1000 ft.

“Sensor miswired” 1.

Open wire between sensor and analyzer.

1. Check wiring.

2. Bad preamplifier. 2. Replace preamplifier. (Code 02 only)

“Temp error high” 1. Open or shorted RTD. 1. Replace sensor.

“Temp error low” 2. Temperature out of range. 2. Check process temperature.

U17:!45

U17: