4-9 TROUBLESHOOTING

Troubleshooting procedures are listed in Table 4-1 below. If the problem cannot be solved or replacement parts

are necessary, contact your authorized Bush Hog dealer. Please have ready your machine name, model num-

ber, serial number, purchase date and exact cause or description of problem.

Table 4-1 Troubleshooting

PROBLEM PROBABLE CAUSE REMEDY

Uneven or streaked stubble Cylinder control valve not in “float” Place valve in “float” position

position.

Blades dull, rounded or broken Reverse or replace

Low PTO speed (heavy crops) Operate at 540 or 1000 rpm

High PTO speed (light crops) Operate at 540 or 1000 rpm

Material collecating on cutter bar Reduce cuter bar lift

Excessive ground speed Use lower gear

Belt slippage Tighten or replace belt

Material dragging on swathboard Remove swathboard

Stubble too long Cutter bar tilted back too far Tilt cutter bar forward

Vibration Blade damaged or missing Replace blade

Disc damaged Replace disc

Tapping or clicking noise Bent blade or rock guard Repair or replace

Blade disc out of time Correct timing

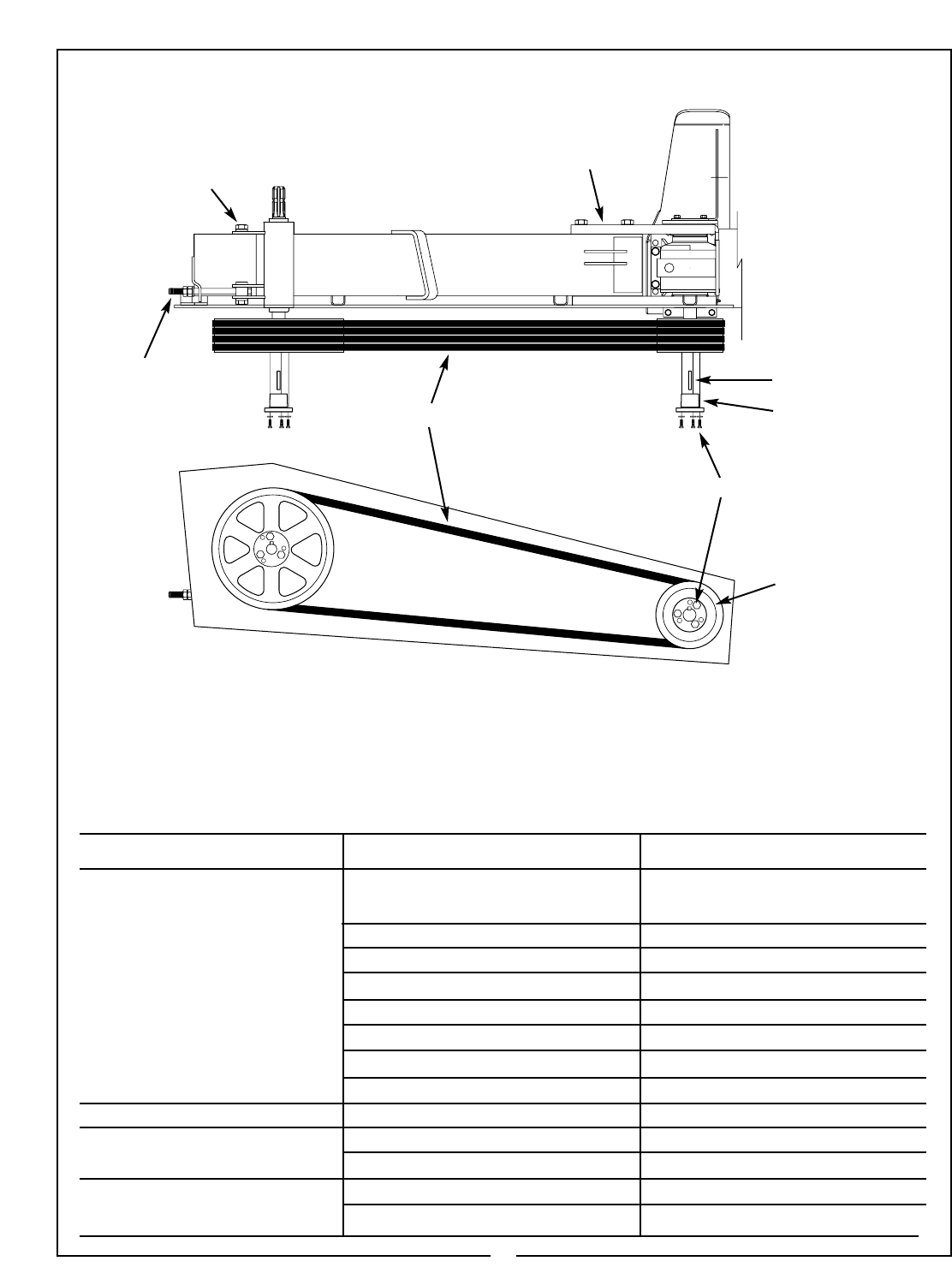

Figure 4-11

Pivot Bolt

Belt Tension

Adjusting Bolt

(1) Belts

(3) Retaining Plate

Key

Bushing

Securing Bolts

(2) Sheave

17