AFTER EACH USE

1. Clean all debris from machine. Replace any

missing or illegible decals.

2. Inspect mower for worn or damaged components.

Repair or replace before next use. Any replace

ment components installed during repair shall

include the components current safety decals

specified by the manufacturer to be affixed to the

component.

3. Store mower in a dry place.

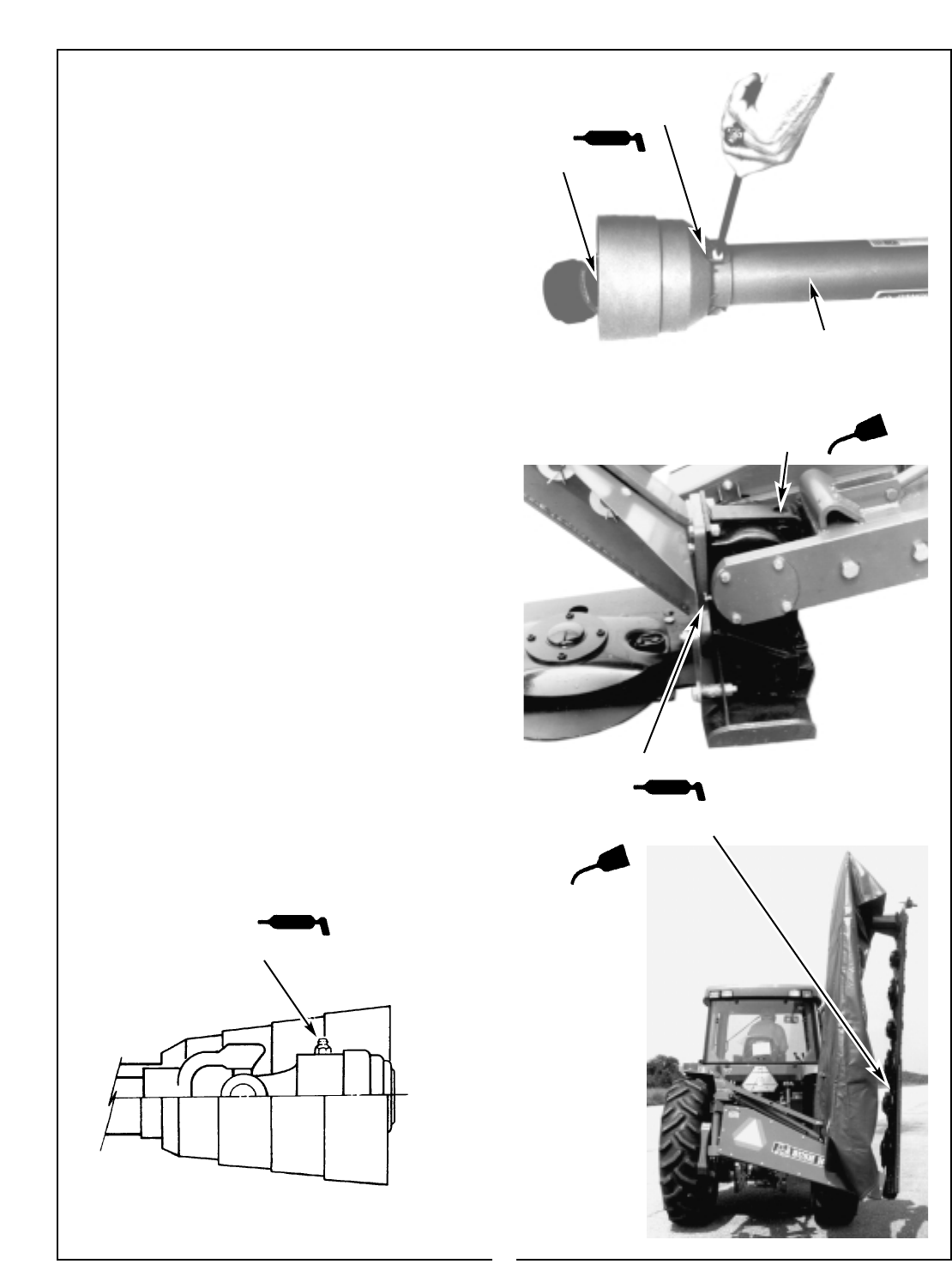

4-2 LUBRICATION (Figures 4-1a, b, c, d)

NOTE

8 HOURS

1. Driveline Universal Joints - Apply multi-purpose

grease with grease gun.

2. Driveline Guard - Apply 2-3 shots of multipur-

pose grease with grease gun to plastic fitting.

3. Cutter Bar Pivot - Apply multi-purpose grease

with grease gun. (2 fittings)

20 HOURS

4. Main Gearbox - Add EP80W-90 gear oil, if nec-

essary, to bring oil level to mark on dip stick.

5. Gear Bar Assembly - Fold mower into the trans-

port position and fasten transport lock. Clean any

grime and filth from around the fill/level plug. Add

EP80W-90 gear oil, if necessary, to bring oil level

up to the fill hole.

6. Overrunning Clutch - Apply multi-purpose grease

with grease gun.

7. Driveline - Disconnect PTO driveline, pull the two

sections apart, apply thin coat of multi-purpose

grease to outside of inner (male)

section.Reassemble sections and install. Pull

each section to be sure driveline and shields are

securely connected. Make certain PTO shielding

is in good condition.

8. Mast Pivot - Apply multi-purpose grease with

grease gun. (Figure 4-4)

The multi-purpose grease referenced in this

section is an NLGI Grade 2 type grease.

Figure 4-1a

(2) BEfore Each Use

(1) Before Each Use

(7) 20 Hours

To Remove Yoke Shield: Turn all three tabs 1/4 turn

with screwdriver and remove tabs. Slide cover and

plastic tube back.

Figure 4-1b (4) 20 Hours

(3) Before Each Use

Figure 4-1c

Overrunning Clutch (6) 20 Hours

Figure 4-1d (5) 20 Hours - Gear Bar Lube

13