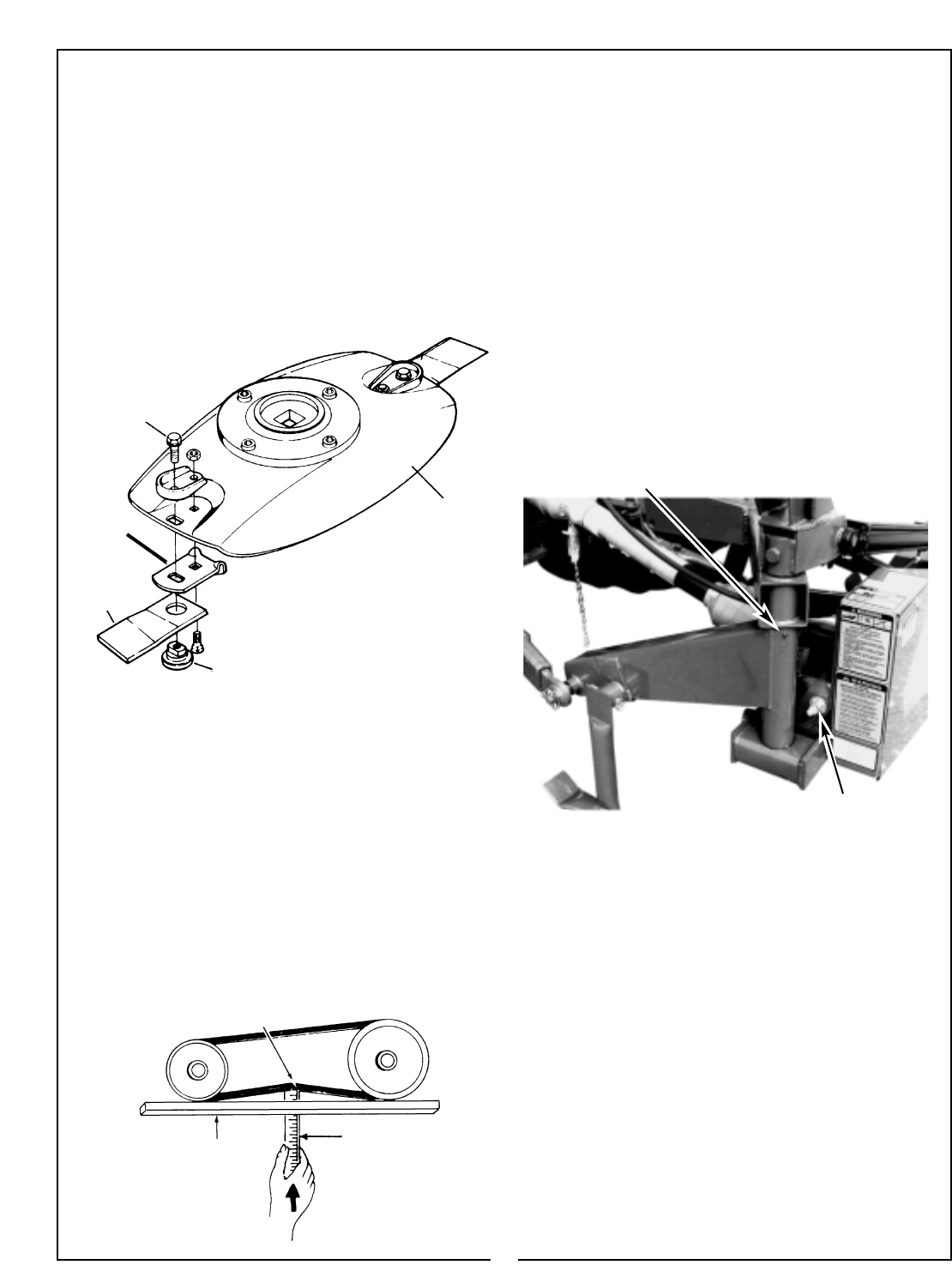

4-3 BLADE REPLACEMENT

The disc mower blades each have two cutting

edges. When one edge becomes dull or damaged,

remove the bolt and turn the blade over, Nuts can be

re-used if not damaged. If both cutting edges of the

blade have been used, the blades must be replaced.

Always replace both blades on a spindle to retain

balance. When replacing blades, the attaching

bolt and nut should also be replaced. Use only

genuine Bush Hog replacement parts. (Figure 4-2)

4-4 BELT ADJUSTMENT

Belt tension should be checked after first 2 hours of

operation and thereafter every 40 hours to get maxi-

mum life from drive belts and best performance from

mower. To check adjustment, push upward through

hole in bottom of belt shield with 10 lbs. of force. Belt

should deflect approximately 1/2 inch (Figure 4-3).

To increase tension, loosen jackshaft assembly pivot

bolt, (Figure 4-8), loosen jam nut, and turn adjusting

nut (Figure 4-4) clockwise. Tighten pivot bolt and

jam nut.

Figure 4-2

Blade Bolt

Blade Disc

Blade

Stop

Blade

Nut

When replacing blades, insure that

shoulder of blade nut is seated into

the blade stop and blade disc.

Torque blade bolt to 50 ft. lbs. Strike

nut with hammer and retorque.

Figure 4-3

Approximately 1/2”

Straight Edge

Ruler

10 lbs. of force

4-5 BELT REPLACEMENT

Replacement belts are sold in matched sets. To

maintain an equal amount of tension on each belt,

replace all belts at same time. Use only genuine

Bush Hog replacement parts. Replace as follows:

A. Remove belt shield cover.

B. Loosen jackshaft assembly pivot bolt, loosen

jamnut, and turn adjusting nut (Figure 4-4) counter-

clockwise to relieve belt tension.

C. Remove belts.

D. Install new matched set of belts.

E. Tighten adjusting nut until belts deflect 1/2”

with 10 lbs. of force applied (Figure 4-3). Rotate

belt pulleys 6 complete revolutions to seat the

belts into the pulleys. Tighten adjusting nut a sec-

ond time until belts deflect 1/2” with 10 lbs. of force

applied. Tighten jam nut on adjusting nut and tighten

assembly pivot bolt.

F. Install belt shield cover.

Figure 4-4 (8) Mast Pivot Grease Fitting

Belt Tension Adjusting Nut

4-6 SPINDLE HOUSING REMOVAL AND

REASSEMBLY

A. Lower cutter bar to rest on a flat surface that

will support the entire length. (Figure 4-5)

B. Remove the cap and the blade disc assembly

retaining nut on desired blade disc assembly. The

outer gear housing assembly has the crop divider

asembled to the blade disc assembly. The cap for

the crop divider must be removed to provide access

to the retaining nut.

STANDARD CROP DIVIDER - Detach the cap and

cutter by removing the four (4) capscrews attaching

the cap to the crop divider. (Figure 4-6)

OPTIONAL CROP DIVIDER - Remove cap by loos-

ening jam nut, turn threaded rod counterclockwise

so cap moves down on threaded rod approximately

1-1/2” tilt cap sideways and remove out the top of

crop divider. (Figure 4-7)

14