Project EVEREST DD66000

even-order distortion components. All suspension elements are tailored for

maximum mechanical displacement linearity.

The cone is comprised of a special layered paper pulp matrix with proprietary

Aquaplas ™ damping which offers more pistonic behavior throughout the

woofer’s operating bandwidth, and controlled cone breakup beyond it.

A thick wall, cast aluminum frame is u

sed to rigidly support the motor structure.

This fully vented frame and motor design also serves to minimize the

backpressure under the dome and spider, which helps to reduce harmonic

distortion to even lower levels. JBL’s Vented Gap Cooling (VGC) is

incorporated within the motor structure, and lowers the operating temperature

of the coil during moments of high power operation.

Altogether these design factors provide reduced harmonic distortions at very

low and high acoustic output, improved power handling, reduced power

compression, and more consistent spectral balance with varying input drive

level.

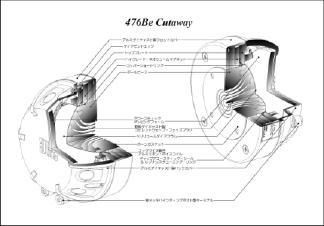

476Be High Frequency Compression Driver and Horn

See Figure 3

The 476Be High Frequency Compression driver makes use of a 100 mm

diameter, pure Beryllium diaphragm with 99 mm aluminum Edge-wound coil,

operating into JBL’s existing Rapid Flare type, Coherent Wave phasing plug.

The use of an efficient Neodymium rare-earth motor structure with new Copper

Sleeved pole piece maintains maximum gap flux and reduced coil inductance at

a minimum size and weight. The combination of these features has created a

driver that can deliver superior sound quality regardless of acoustic power

output with very little distortion and power compression.

Figure 3 – 476Be section view