7800 SERIES RM7824A RELAY MODULE

65-0155—1

10

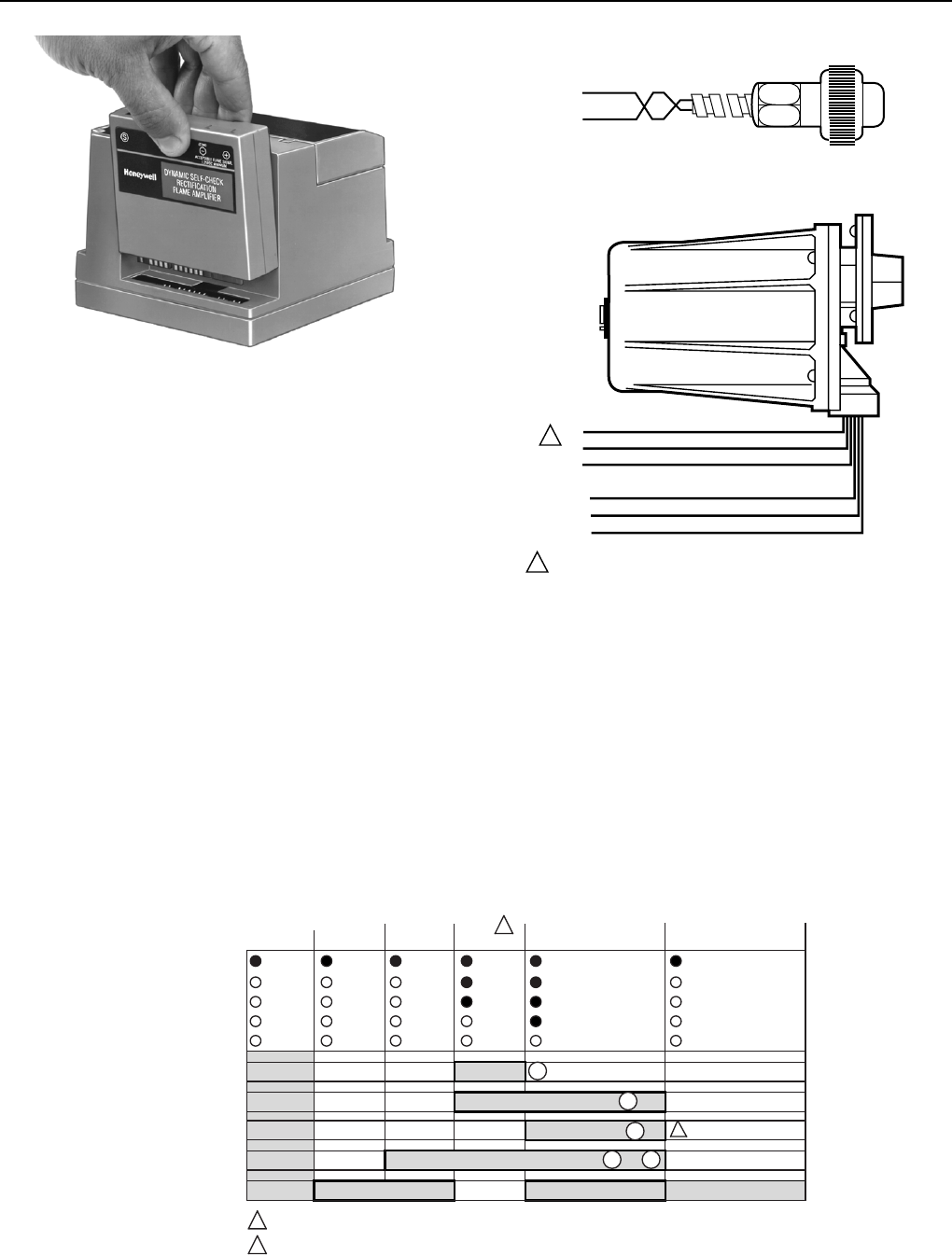

Fig. 10. Flame signal amplifier mounting.

Installing Flame Detector

NOTE: Table 2 and Fig. 11 list the flame detectors available

for use with the RM7824A. Make sure the correct

combination of amplifier and flame detector(s) is used.

Proper flame detector installation is the basis of a safe and

reliable flame safeguard installation. Refer to the instructions

packed with the flame detector and the equipment

manufacturer instructions.

Keep the flame signal leadwires as short as possible from the

flame detector to the wiring subbase. Capacitance increases

with wire length, reducing the signal strength. The maximum

permissible leadwire length depends on the type of flame

detector, leadwire and conduit. The ultimate limiting factor in

the flame detector leadwire is the flame signal (see Table 6).

BLUE

YELLOW

WHITE

WHITE

RED

BLACK

F

G

22

M7594

SOLID STATE SELF-CHECKING

ULTRAVIOLET (C7024E,F - E SHOWN)

1

1

FLAME DETECTOR LEADS ARE COLOR CODED. THE BLUE LEAD

MUST BE CONNECTED TO THE F TERMINAL AND THE YELLOW

MUST BE CONNECTED TO THE G TERMINAL. THE UV SENSING

TUBE IS POLARITY SENSITIVE. REVERSING THE LEADS EVEN

MOMENTARILY CAN DAMAGE OR DESTROY THE UV TUBE.

24Vdc (–)

3

24Vdc (–)

WHITE

BROWN

F

G

INFRARED (C7015)

Fig. 11. Flame detector wiring.

OPERATION

Sequence of Operation

The RM7824A has the following operation sequence (see Figs. 12 and 14).

Fig. 12. RM7824A sequence.

POWER

00

LED

DISPLAY

OPERATING

CONTROLLER

AND LIMITS

BURNER

START

FLAME

SIGNAL

INITIATE

ALARM

POWER

STANDBY

POWER POWER

PILOT

FLAME

MAIN

PFEP

4 OR 10 SEC

PILOT

FLAME

MAIN

POWER

RUN

STANDBY

10

IGNITION

INTERMITTENT PILOT

MAIN VALVE

LIMITS AND BURNER CONTROL CLOSED

9

8

10

+ 6

TO

M5135B

00

POWER

SAFE-

START

MAIN FUEL VALVE WILL BE ENERGIZED DURING PFEP IF FLAME IS PROVEN.

RM7890A1031 PFEP IS FIXED 30 SECOND.

1

2

2

1

ALARM

S S C

SAFE START CHECK

FLAME PROVING