Form No. S3423-1112

Supersedes S3423-912

Page 5 of 28

1 Pump output (feet of head) @ GPM at top of column.

sledoMpmuP spmuPfo.oN

MPGNIDERIUQERETARWOLFRETAW

7 9 21 51 61

1-CFROD15.825.72525.2222

2-CFROD27555055444

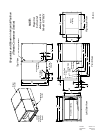

Loop Pump Modules and Pump Outputs for Ground Loop Installations 1

Correction Factors @ Increased Water Flows

wolFdetaR

sulP

gnilooC gnitaeH

HutB sttaW HutB sttaW

MPG2500.1889.0600.1200.1

MPG3700.1489.0900.1300.1

MPG4800.1979.0110.1300.1

1 Loop antifreeze protection must be determined based on loop design and geographic location.

2 Must not be denatured with any petroleum based product.

epyT

noitcetorPezeerFroferutarepmeTmuminiM

)C°2.21-(F°01 )C°4.9-(F°51 )C°7.6-(F°02 )C°9.3-(F°52

lonahteM%52%12%61%01

lonahtE 2 %92%52%02%41

locylGenelyporPedarGdooFPSU%001%72%42%02%31

Antifreeze Percentages by Volume for Ground Loop Installations 1

Ratings Based on Approved Compressor and Fossil Fuel A-Coil

ROSSERPMOC

NOITCES

LEDOM

lissoF

leuF

lioC-A

.oNdraB

11

1

11

metsyS

yticapaC

noitaludoM

wolFdiulF

MPGetaR

MFCwolfriA

—pmuPtaeHpooLdnuorG 8991:1-65231OSIotdeifitreC&detseT

enirBgnilooC

F°86daoLtraP/F°77daoLlluF

enirBgnitaeH

F°14daoLtraP/F°23daoLlluF

yticapaC

HUTB

REE

W/UTB

yticapaC

HUTB

POC

1S63CTG

1

lluF

traP

8

0021

058

000,93

003,82

02.81

05.62

002,72

004,12

00.4

05.4

1S84CTG

1

lluF

traP

21

0051

0511

000,84

000,73

05.71

06.22

000,53

000,82

08.3

00.4

1S06CTG

1

lluF

traP

51

0081

0031

000,95

005,44

05.61

00.12

000,54

000,73

06.3

57.3

LEDOM

metsyS

yticapaC

noitaludoM

wolFdiulF

MPGetaR

MFCwolfriA

—pmuPtaeHretaWdnuorG 8991:1-65231OSIotdeifitreC&detseT

F°95TWE—gnilooC F°05TWE—gnitaeH

yticapaC

HUTB

REE

W/UTB

yticapaC

HUTB

POC

1S63CTG

1

lluF

traP

6

0021

058

000,24

006,92

04.32

08.13

005,43

007,42

09.4

00.5

1S84CTG

1

lluF

traP

7

0051

0511

000,35

005,73

00.22

00.62

000,44

000,33

05.4

07.4

1S06CTG

1

lluF

traP

9

0081

0031

000,36

005,54

08.02

52.52

000,45

005,93

02.4

03.4

.gnipmupretawrofecnawollattawsedulcni)spmuPtaeHriA-ot-enirBdnariA-ot-retaW(1-65231dradnatSOS

I

.erutarepmetriagniretneBDF86nodesabyticapacgnitaeH.erutarepmetriagniretneBWF2.66,BDF6.08nodesabyticapacgniloo

C

All Models are Energy Star qualified for Ground Loop and Ground Water Applications.

For Use with Gas or Oil Furnace as Dual Fuel Installation

The GTC Compressor Unit Sections are approved for use with certain 3rd Party A-Coils.

See Below.

1 See Cross-Reference Chart (Page 2) for approved Bard/ADP Coil part numbers.

Charge must be adjusted when using a Fossil Fuel A-Coil. See Installation Manual.

A coil spacer with a minimum height of 6" must be used on all Oil Furnaces to protect the coil drain pan and ensure even airflow across the coil.

GTLS-SK2-1 Line Set Stub Kit is required for installation to make connections to the GTC Compressor Section.