1. While obtaining a process solution sample (it is recommended that

the sample is taken close to the sensor), record the pH value that

is shown on the analyzer/transmitter display.

2. Measure and record the pH of the process solution sample with

another temperature compensated, calibrated pH instrument. For

best results, standardization should be performed at the process

temperature.

3. Adjust the analyzer/transmitter value to the standardized value.

5.2 MODEL 396P and 396PVP ORP SENSORS

5.2.1 SENSOR PREPARATION

. Most industrial applications have

a number of ORP reactions occurring in sequence or simultaneously.

There can be several components that are oxidized or reduced by

the reagents that are used. Theoretically, the ORP potential is

absolute because it is the result of the oxidation-reduction equilibri-

um. However, the actual measured potential is dependent on many

factors, including the condition of the surface of the ORP platinum

electrode. Therefore, the sensor should be allowed 1-2 hours to

become “conditioned” to the stream when first set-up or after

being cleaned.

5.2.2 ORP CALIBRATION

1. Make a temporary electrical connection between the sensor and

the instrument.

2. Obtain an ORP standard solution, or a standard solution can also be

made quite simply by adding a few crystals of quinhydrone to either

pH 4 or pH 7 buffer. Quinhydrone is only slightly soluble therefore a

few crystals will be required. (Refer to Section 4.3. for an alternate

ORP standard solution).

3. Immerse the sensor in the standard solution. Allow 1-2 minutes for

the ORP sensor to stabilize.

4. Adjust the standardize control of the instrument to the solution value

shown in Table 5-1 (below) or on the label of the standard solution.

The resulting potentials, measured with a clean platinum electrode

and saturated KCl/AgCl reference electrode, should be within ±20

millivolts of the value. Solution temperature must be noted to ensure

accurate interpretation of results. The ORP value of saturated quin-

hydrone solution is not stable over long periods of time. Therefore,

these standards should be made up fresh each time they are used.

5. Remove the sensor from the buffer, rinse and install in the process.

MODEL 396P and 396PVP SECTION 5.0

START UP AND CALIBRATION

SECTION 5.0

START UP AND CALIBRATION

5.1 MODELS 396P and 396PVP pH SENSORS

5.1.1 SENSOR PREPARATION. Shake down the sensor

to remove any air bubbles that may be present at the tip of

the pH glass bulb. In most cases, the pH sensor can simply

be installed as shipped and readings with an accuracy of ±

0.6 pH may be obtained. To obtain greater accuracy or to

verify proper operation, the sensor must be calibrated as a

loop with its compatible analyzer or transmitter.

5.1.2 pH CALIBRATION. After a temporary connection is

established between the sensor and the instrument, a buffer

calibration may be performed. Consult appropriate pH/ORP

analyzer or transmitter instruction manual for specific calibra-

tion and standardization procedures, or see below for recom-

mended two-point buffer calibration procedure.

Recommended two-point buffer calibration procedure:

Select two stable buffer solutions, preferably pH 4.0 and 10.0

(pH buffers other than pH 4.0 and pH 10.0 can be used as long

as the pH values are at least two pH units apart).

NOTE

A pH 7.0 buffer solution reads a mV value of approxi-

mately zero, and pH buffers read approximately 59.1

mV for each pH unit above or below pH 7.0. Check the

pH buffer manufacturer specifications for millivolt values

at various temperatures since it may affect the actual

value of the buffer solution mV/pH value.

1. Immerse sensor in the first buffer solution. Allow sensor

to adjust to the buffer temperature (to avoid errors due to

temperature differences between the buffer solution and

sensor temperature) and wait for reading to stabilize.

Value of buffer can now be acknowledged by

analyzer/transmitter.

2. Once the first buffer has been acknowledged by the ana-

lyzer/transmitter, rinse the buffer solution off of the sensor

with distilled or deionized water.

3. Repeat steps 1 and 2 using the second buffer solution.

4. Once the analyzer/transmitter has acknowledged both

buffer solutions, a sensor slope (mV/pH) is established (the

slope value can be found within the analyzer/ transmitter).

5. The slope value should read about 59.1 mV/pH for a new

sensor and will decrease over time to approximately 47-

49 mV/pH. Once the slope reads below the 47-49 mV/pH

range, a new sensor should be installed to maintain accu-

rate readings.

Recommended pH Sensor S

tandardization:

For maximum accuracy, the sensor can be standardized online

or with a process grab sample after a buffer calibration has

been performed and the sensor has been conditioned to the

process. Standardization accounts for the sensor junction

potential and other interferences. Standardization will not

change the sensor’s slope but will simply adjust the analyzer’s

reading to match that of the known process pH.

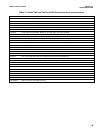

pH 4 Solution pH 7 Solution

Temp

°°

C 20 25 30 20 25 30

Millivolt Potential 268 264 260 94 87 80

TABLE 5-1. ORP of Saturated Quinhydrone

Solution (In Millivolts)

24