Micro-Tech 1200 Amplifier Service Manual

14

TEST 4: AC POWER DRAW

Spec: 100 Watts maximum quiescent.

Initial Conditions: Controls per standard.

Procedure: With no input signal and no load, measure

AC line wattage draw. If current draw is excessive,

check for high AC line voltage or high bias voltage.

TEST 5: COMMON MODE REJECTION

Spec at 100 Hz: –70 dB.

Spec at 20 kHz: –50 dB.

Initial Conditions: Controls per standard.

Procedure: No load. Inject a 0 dBu (.775VRMS) 100 Hz

sine wave into each channel, one channel at a time, with

inverting and non-inverting inputs shorted together. At

the output measure less than –44 dBu (4.9mVRMS).

Inject a 0 dBu 20 kHz sine wave into each channel, one

channel at a time, with inverting and non-inverting

inputs shorted together. At the output measure less

than –24 dBu (49mVRMS). For Main Modules with board

numbers lower than D 7993-5 adjust N100 and N200 to

calibrate CMR. For Main Modules with board number D

7993-5 or greater adjust R921 and R1021.

TEST 6: VOLTAGE GAIN

Spec 26dB Gain: Gain of 20.0 ±3%.

Spec 0.775V Sensitivity: ±6%.

Spec 1.4V Sensitivity: +12%/–6%.

Initial Conditions: Controls per standard.

Procedure: No load connected. Inject a 0.775 VAC 1 kHz

sine wave with the Sensitivity Switch in the 26 dB

position. Measure 15.5 VAC ±0.5 VAC at the amplifier

output. Inject a 0.775 VAC 1 kHz sine wave with the

Sensitivity Switch in the 0.775V position. Measure 50.6

VAC ±3 VAC at the amplifier output. Inject a 1.4 VAC 1

kHz sine wave with the Sensitivity Switch in the 1.4V

position. Measure 50.6 VAC +6/–3 VAC at the amplifier

output. Return the Sensitivity Switch to the 26 dB

position.

TEST 7: PHASE RESPONSE

Spec: ±10° from 10 Hz to 20 kHz at 1 Watt.

Initial Conditions: Controls per standard, 8 ohm load on

each channel.

Procedure: Inject a 1 kHz sine wave and adjust for 1 Watt

output (2.8 VAC). Check input and output signals

against each other, input and output signals must be

within 10° of each other.

TEST 8: LEVEL CONTROLS

Electrical Checkout Procedures

Spec: Level controlled by level controls.

Initial Conditions: Controls per standard.

Procedure: No Load. Inject a 1 kHz sine wave. With level

controls fully clockwise you should see full gain. As

controls are rotated counterclockwise, observe similar

gain reduction in each channel. When complete, return

level controls to fully clockwise position.

TEST 9: CURRENT LIMIT

Spec: Current Limit at 30 Amps, ±2 Amps

Initial Conditions: Controls per standard.

Procedure: Load each channel to 1 Ohm. Inject a 1 kHz

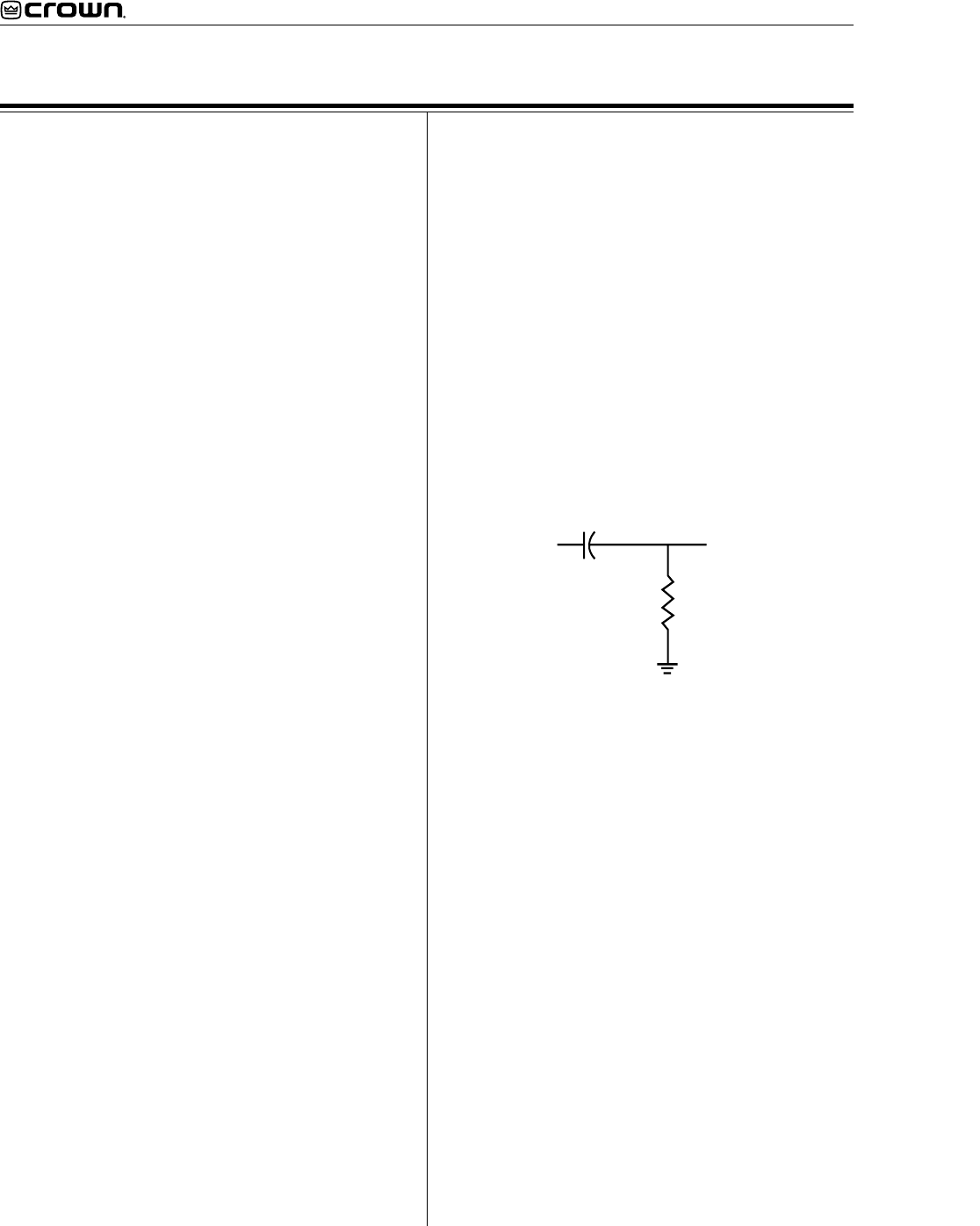

differentiated (or 10% duty cycle) square wave. See

figure 4. Increase output level until current limit occurs.

Current limit should occur at 30 ±2 Amps (30 Vpk).

Observe clean (no oscillations) current clipping.

In

Out

.047 uF

1K Ohm

Figure 4. Differentiator Circuit

TEST 10: SLEW RATE & 10 KHZ SQUARE WAVE

Spec: 13 - 15 V/µS.

Initial Conditions: Controls per standard.

Procedure: Load each channel to 8 ohms. Inject a 10 kHz

square wave to obtain 65 volts zero-to-peak at each

output. Observe the slope of the square wave. It should

typically measure 13 to 15 V/µS. Also, the square wave

must not include overshoot, ringing, or any type of

oscillation.

TEST 11: CROSSTALK

Spec: -60dB at 20 kHz.

Initial Conditions: Controls per standard. Terminate

input of channel not driven with 600 ohms.

Procedure: 8 ohm load on each channel. Inject a 20 kHz

sine wave into the Channel 1 input and increase output

level to 33 VAC. Measure less than 33 mVAC at the

output of Channel 2. Inject a 20 kHz sine wave into the

Channel 2 input and increase output level to 33 VAC.

Measure less than 33 mVAC at the output of Channel 1.

TEST 12: OUTPUT POWER

Spec at 8 Ohm Stereo: >= 320W at 0.1% THD.