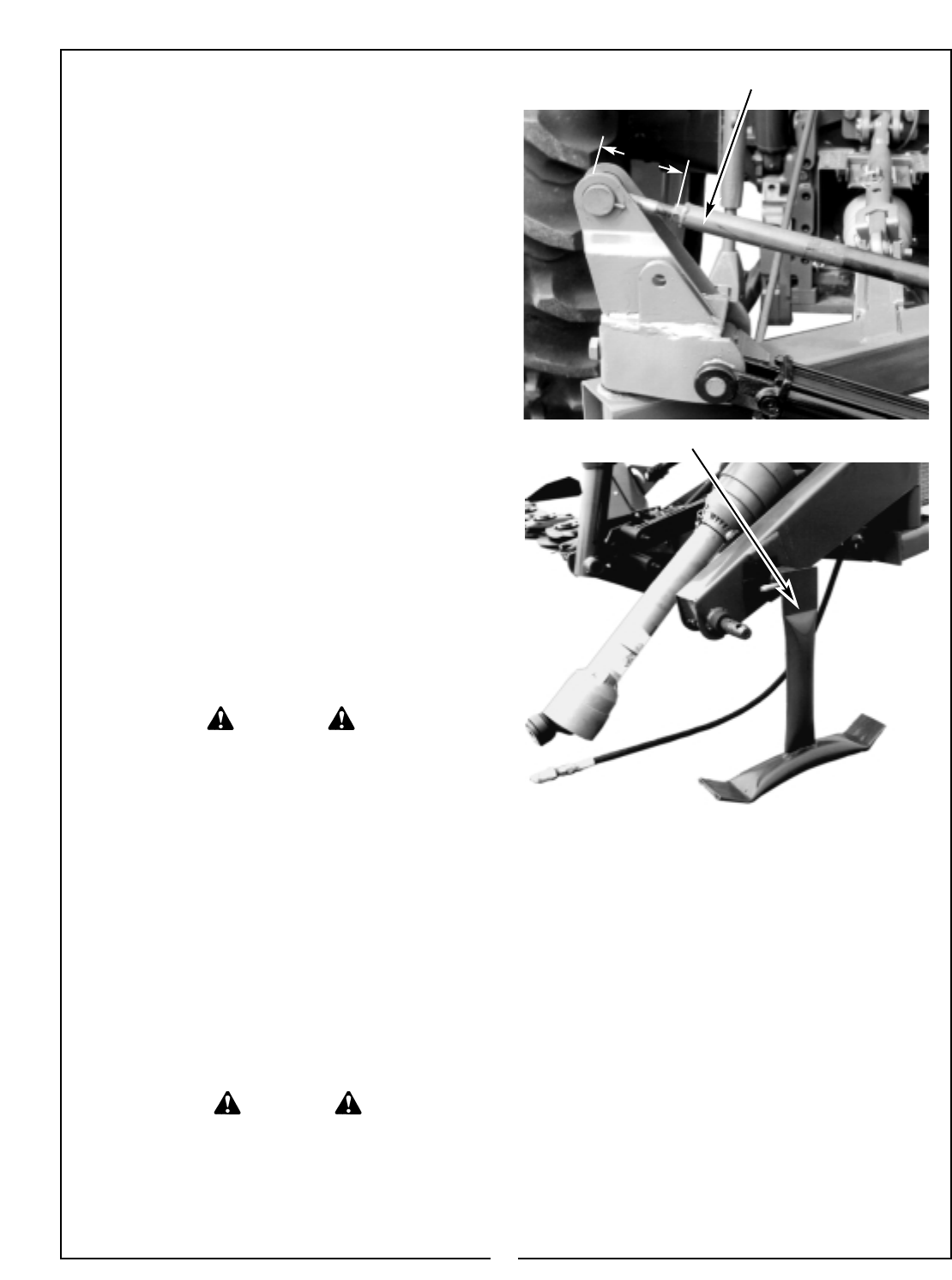

3-7 CUTTER BAR HELPER SPRING

ADJUSTMENT

(9’ MODELS ONLY)

The 9’ models are equipped with a helper spring

assembly to transfer cutter bar weight from the

outer end of the cutter bar back to the frame

assembly. The recommended minimum adjustment

measurement is 5-1/2” from under the bolt head to

the end of the rod weldment nut. (Figure 3-5) To

transfer more weight, shorten the measurement. To

transfer less weight, lengthen the measurement. Be

advised, the shorter the measurement, the less the

outer end of the cutter bar can reach down.

3-8 UNHITCHING FROM TRACTOR AND

STORAGE

To prevent rust, always clean all debris from mower

after use. Store in a clean, dry place preferably with

a hard, level floor. Clean and paint any areas where

paint is missing. Apply a light coat of grease to cylin-

der rod..

Unhitch mower as follows:

A. Pin parking stand in the down position as

shown in Figure 3-6.

B. Unfold cutter bar and lower to ground.

C. Lower 3-point hitch to rest on parking stand.

Make certain all pressure is relieved from cutter bar

cylinder.

D. Disconnect PTO driveline, hydraulic hose, and

3-point links.

WARNING

TO AVOID SERIOUS INJURY OR DEATH:

ALWAYS STORE MOWER WITH THE

CUTTER BAR IN THE UNFOLDED

(HORIZONTAL) POSITION.

Figure 3-5 Helper Spring Assembly

5-1/2”

Figure 3-6 Parking Stand

SECTION IV

MAINTENANCE

4-1 MAINTENANCE CHECK LIST

Perform scheduled maintenance as outlined below.

Lower implement to ground, turn off tractor, and set

parking brake before doing maintenance inspections

or work. Some checks may require raising machine

off ground and supporting with blocks. All bolts

should be torqued as indicated in torque at end of

manual unless otherwise indicated.

WARNING

THE MOWER CAN FALL FROM

HYDRAULIC SYSTEM FAILURE. TO AVOID

SERIOUS INJURY OR DEATH, SECURELY

SUPPORT MOWER BEFORE WORKING

UNDERNEATH.

BEFORE EACH USE

1. Perform LUBRICATION per paragraph 4-2.

2. Check blades and spindles to be sure that no

foreign objects such as wire or steel strapping

bands are wrapped around them.

3. Inspect blades for wear. Replace if necessary

per paragraph 4-3. Always replace both blades

with two blades equal in weight. Use only

genuine Bush Hog replacement parts.

4. Check blade bolts for tightness. Tighten to 50 ft./lbs.

5. Make certain all shields are in place and in good

condition. Repair or replace any missing or dam-

aged shields.

6. Check tractor tire air pressure. Refer to tractor oper-

ator’s manual.

7. During operation, listen for abnormal sounds which

might indicate loose parts, damaged bearings, or

other damage. Correct any deficiency before contin-

uing operation.

12