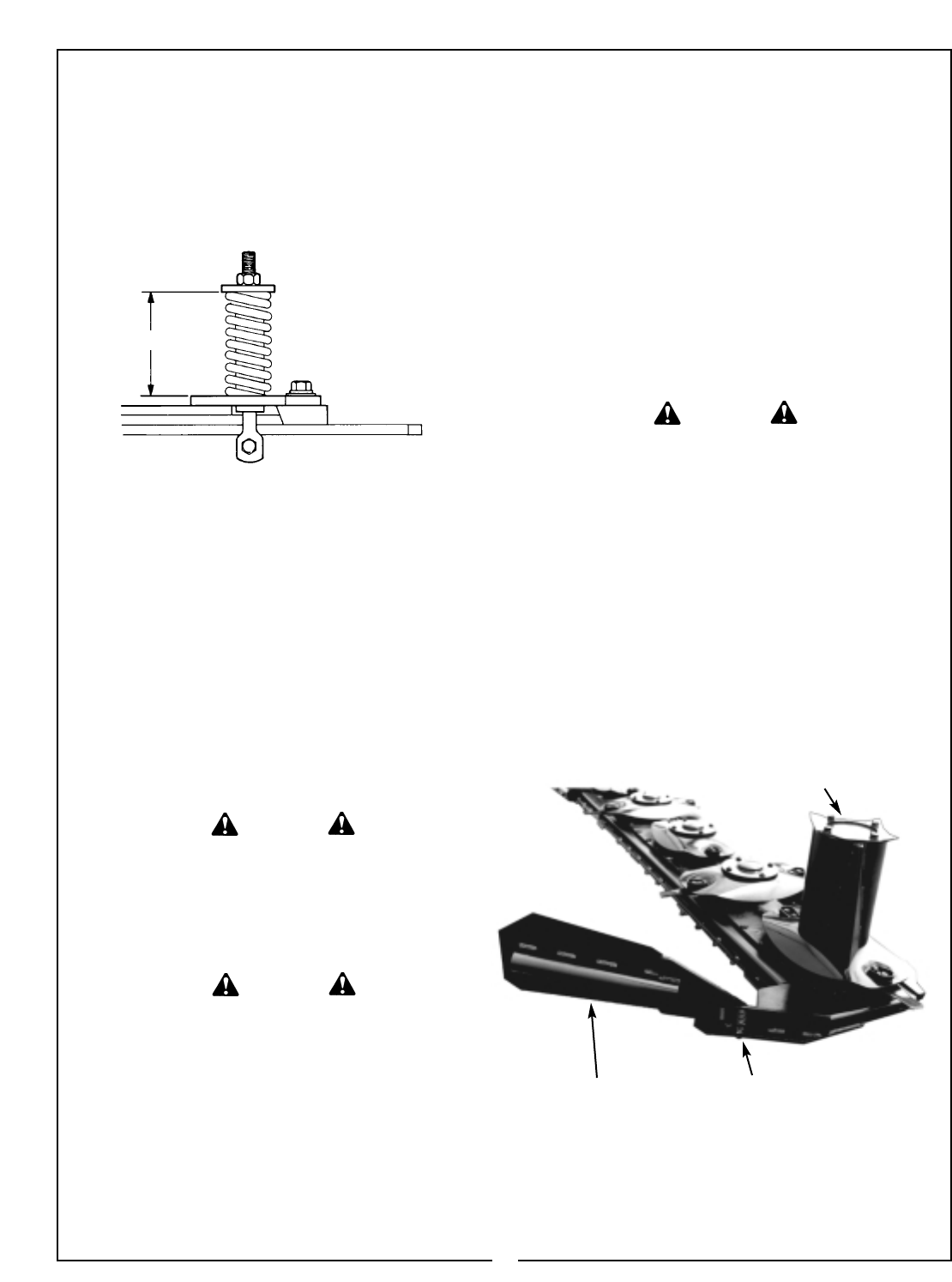

Breakaway pressure is regulated by the tension of

the latch springs (Figure 3-3). Spring length as

shipped from the factory is 4-1/8” and is satisfactory

for most conditions. Breakaway pressure can be

increased by turning spring retaining nuts clockwise

or decreased by turning counterclockwise. DO NOT

COLLAPSE SPRING TO LESS THAN 3-3/4” OR

SPRING WILL BECOME SOLID BEFORE LATCH

CAN TRIP.

Figure 3-3

Breakaway Latch Spring

4-1/8”

3-5 OPERATION

A. Perform BEFORE EACH USE maintenance

listed in paragraph 4-1.

B. Pin parking stand and transport latch in the

work position.

C. Start tractor. Set tractor 3-point hitch depth

control or install the optional check chain assembly

to stop with the horizontal main frame pivot approxi-

mately 20” from the ground. (Figure 2-4) Check

chain retainers should be installed onto tractor rear

casting using top link pin.

D. Lower cutter bar parallel to ground. Lower 3-

point hitch to work position. Place control valve for

cutter bar cylinder in “float” position.

TO AVOID SERIOUS INJURY OR DEATH:

STAY CLEAR OF ROTATING DRIVELINE.

DO NOT OPERATE WITHOUT

DRIVELINE SHIELDS IN PLACE AND IN

GOOD CONDITION.

TO AVOID SERIOUS INJURY OR DEATH:

STAND CLEAR OF ROTATING MOWER

BLADES UNTIL ALL MOTION HAS

STOPPED. TO AVOID ACCIDENTAL

FALL FROM TRACTOR AND POSSIBLE

INJURY FROM MOWER, IT IS RECOM-

MENDED THAT TRACTOR BE EQUIPPED

WITH ROLLOVER PROTECTIVE SYSTEM

(ROPS) AND THAT A SEAT BELT BE

USED FOR ALL MOWING OPERATIONS.

DANGER

DANGER

E. With tractor at idle speed, engage PTO drive.

Set tractor throttle for 540 PTO rpm for models GHM

700, GHM 800, and GHM 900 and 1000 PTO rpm

for models GHM 1800 and GHM 1900.

F. Place tractor in a gear that will give proper

speed for terrain and crop conditions , then begin

mowing. Tractor forward speed should be controlled

by gear selection, not engine speed. For maximum

efficiency, forward speed should allow mower to

maintain a constant maximum blade speed.

If tractor engine stalls, do not slip tractor clutch to

allow engine to regain speed as this will exert

tremendous strain on the driveline. When stalling

occurs,disengage PTO drive, move to a cut area,set

tractor throttle at idle, then re-engage PTO drive. If

stalling continues, use lower gear.

3-6 SWATH BOARD

The swath board is manufactured in the correct posi-

tion for most efficient operation. However, some

conditions may require that the swath board be

removed. To do this remove the bolt at the spring

assembly and remove the complete assembly.

DANGER

TO AVOID SERIOUS INJURY OR DEATH

FROM THROWN OBJECTS:

DO NOT OPERATE WITH CURTAIN

GUARD REMOVED. DO NOT OPERATE

WITHOUT CURTAIN GUARD IN GOOD

CONDITION OR REPAIR.

Figure 3-4 Swath Board Assembly

Swath Board Spring Assembly

Crop Divider

11