OUTPUT TRANSISTORS

Output transistors

Q9 through Q12 (Figure 13, Page 13)

are located on the black, finned heat sinks. The replace-

ment procedure is the same as that used for driver tran-

sistors Q7 and Q8.

NOTE: Output transistors

Q9 through Q12 must be

matched for current gain. When replacing output transis-

tors, be sure to replace with devices which have the same

gain and part number as the original transistors. Shure

transistors have a letter suffix in the part number

(i.e.,

86A360A) which serves as a gain code. Transistors with the

same part number and suffix letter have equal current gain.

DIODES

Diodes

Dl5 and Dl6 (Figure 13, Page 13) are located on

the black, finned sinks with the output transistors. Special

care is required to insulate these diodes from the heat sink

while providing good heat transfer from sink to diode.

Heat-

shrinkable tubing or "spaghetti" should be placed over the

diode and connecting leads; the diode should be securely

clamped to the heat sink with the clamp provided.

DIODE BRIDGE RECTIFIER

Silicon diode bridge rectifier

Dl1 is mounted on the

underside of the chassis as shown in Figure 14, Page 14.

When replacing this component, apply Wakefield Type 120

thermal joint compound between the heat sink base of the

rectifier and the chassis to provide good heat transfer to

the chassis. Note that the base of the rectifier is provided

with a locating pin. When installing the rectifier be sure

to position it such that the locating pin fits into the hole

provided for it in the chassis. The terminals are marked to

indicate the ac connections to the power transformer and

the

(+)

and

(-)

dc output connections to filter capacitors

C14 and

C15.

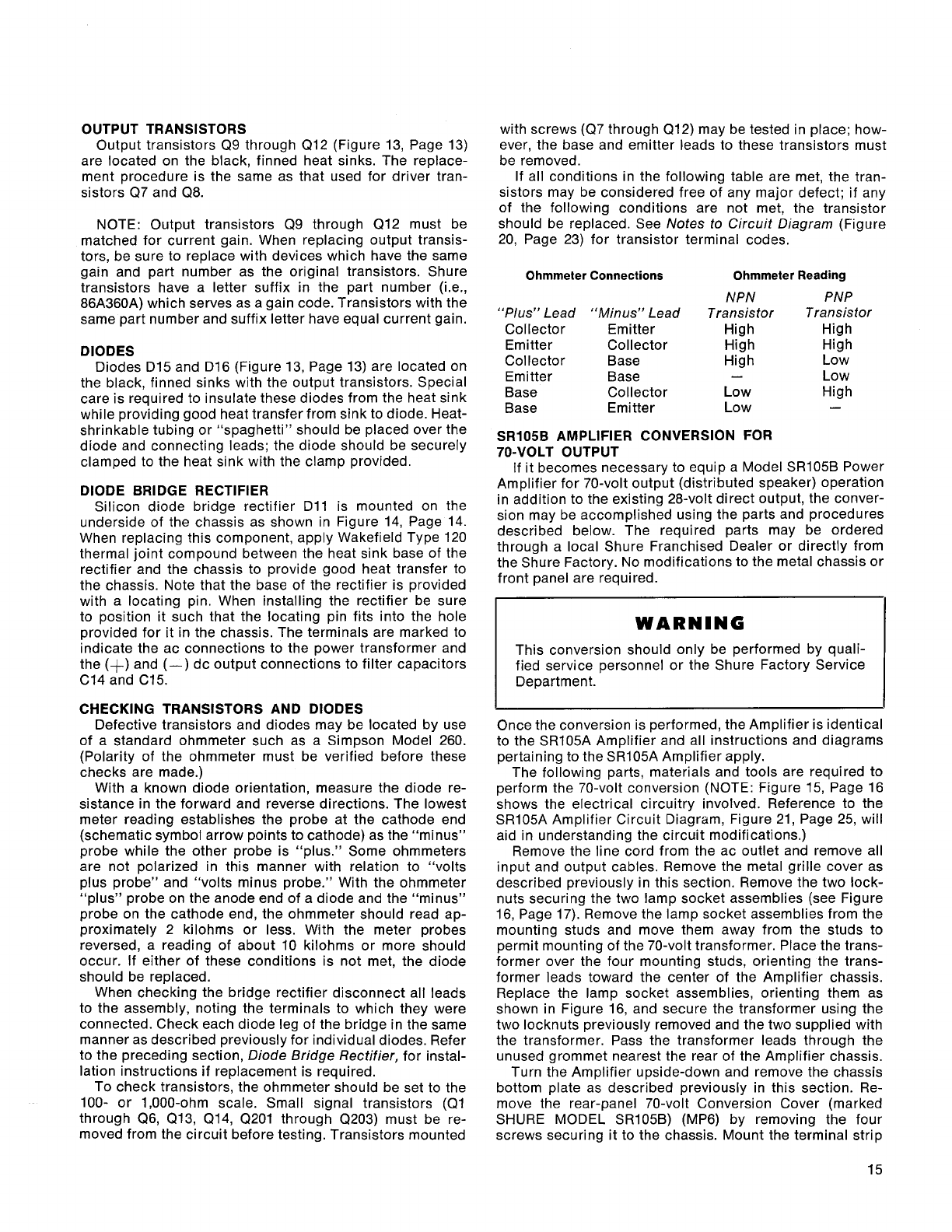

CHECKING TRANSISTORS AND DIODES

Defective transistors and diodes may be located by use

of a standard ohmmeter such as a

Simpson Model 260.

(Polarity of the ohmmeter must be verified before these

checks are made.)

With a known diode orientation, measure the diode re-

sistance in the forward and reverse directions. The lowest

meter reading establishes the probe at the cathode end

(schematic symbol arrow points to cathode) as the "minus"

probe while the other probe is "plus." Some ohmmeters

are not polarized in this manner with relation to "volts

plus probe" and "volts minus probe." With the ohmmeter

"plus" probe on the anode end of a diode and the "minus"

probe on the cathode end, the ohmmeter should read ap-

proximately 2

kilohms or less. With the meter probes

reversed, a reading of about 10 kilohms or more should

occur. If either of these conditions is not met, the diode

should be replaced.

When checking the bridge rectifier disconnect all leads

to the assembly, noting the terminals to which they were

connected. Check each diode leg of the bridge in the same

manner as described previously for individual diodes. Refer

to the preceding section, Diode Bridge Rectifier, for instal-

lation instructions if replacement is required.

To check transistors, the ohmmeter should be set to the

100- or 1,000-ohm scale. Small signal transistors

(Q1

through Q6, Q13, (214, Q201 through (2203) must be re-

moved from the circuit before testing. Transistors mounted

with screws (Q7 through Q12) may be tested in place; how-

ever, the base and emitter leads to these transistors must

be removed.

If all conditions in the following table are met, the tran-

sistors may be considered free of any major defect; if any

of the following conditions are not met, the transistor

should be replaced. See Notes to Circuit Diagram (Figure

20, Page 23) for transistor terminal codes.

Ohmmeter Connections

"Plus" Lead "Minus" Lead

Collector Emitter

Emitter Collector

Collector Base

Emitter Base

Base Collector

Base Emitter

Ohmmeter Reading

NPN PNP

Transistor Transistor

High High

High High

High Low

-

Low

Low High

Low

-

SR105B AMPLIFIER CONVERSION FOR

70-VOLT OUTPUT

If it becomes necessary to equip a Model

SRIOSB Power

Amplifier for 70-volt output (distributed speaker) operation

in addition to the existing 28-volt direct output, the conver-

sion may be accomplished using the parts and procedures

described below. The required parts may be ordered

through a local Shure Franchised Dealer or directly from

the Shure Factory. No modifications to the metal chassis or

front panel are required.

WARNING

This conversion should only be performed by quali-

fied service personnel or the Shure Factory Service

Department.

Once the conversion is performed, the Amplifier is identical

to the

SR105A Amplifier and all instructions and diagrams

pertaining to the

SR105A Amplifier apply.

The following parts, materials and tools are required to

perform the 70-volt conversion (NOTE: Figure 15, Page 16

shows the electrical circuitry involved. Reference to the

SR105A Amplifier Circuit Diagram, Figure 21, Page 25, will

aid in understanding the circuit modifications.)

Remove the line cord from the ac outlet and remove all

input and output cables. Remove the metal grille cover as

described previously in this section. Remove the two lock-

nuts securing the two lamp socket assemblies (see Figure

16, Page 17). Remove the lamp socket assemblies from the

mounting studs and move them away from the studs to

permit mounting of the 70-volt transformer. Place the trans-

former over the four mounting studs, orienting the trans-

former leads toward the center of the Amplifier chassis.

Replace the lamp socket assemblies, orienting them as

shown in Figure 16, and secure the transformer using the

two locknuts previously removed and the two supplied with

the transformer. Pass the transformer leads through the

unused grommet nearest the rear of the Amplifier chassis.

Turn the Amplifier upside-down and remove the chassis

bottom plate as described previously in this section. Re-

move the rear-panel 70-volt conversion Cover (marked

SHURE MODEL

SRlO5B) (MP6) by removing the four

screws securing it to the chassis. Mount the terminal strip