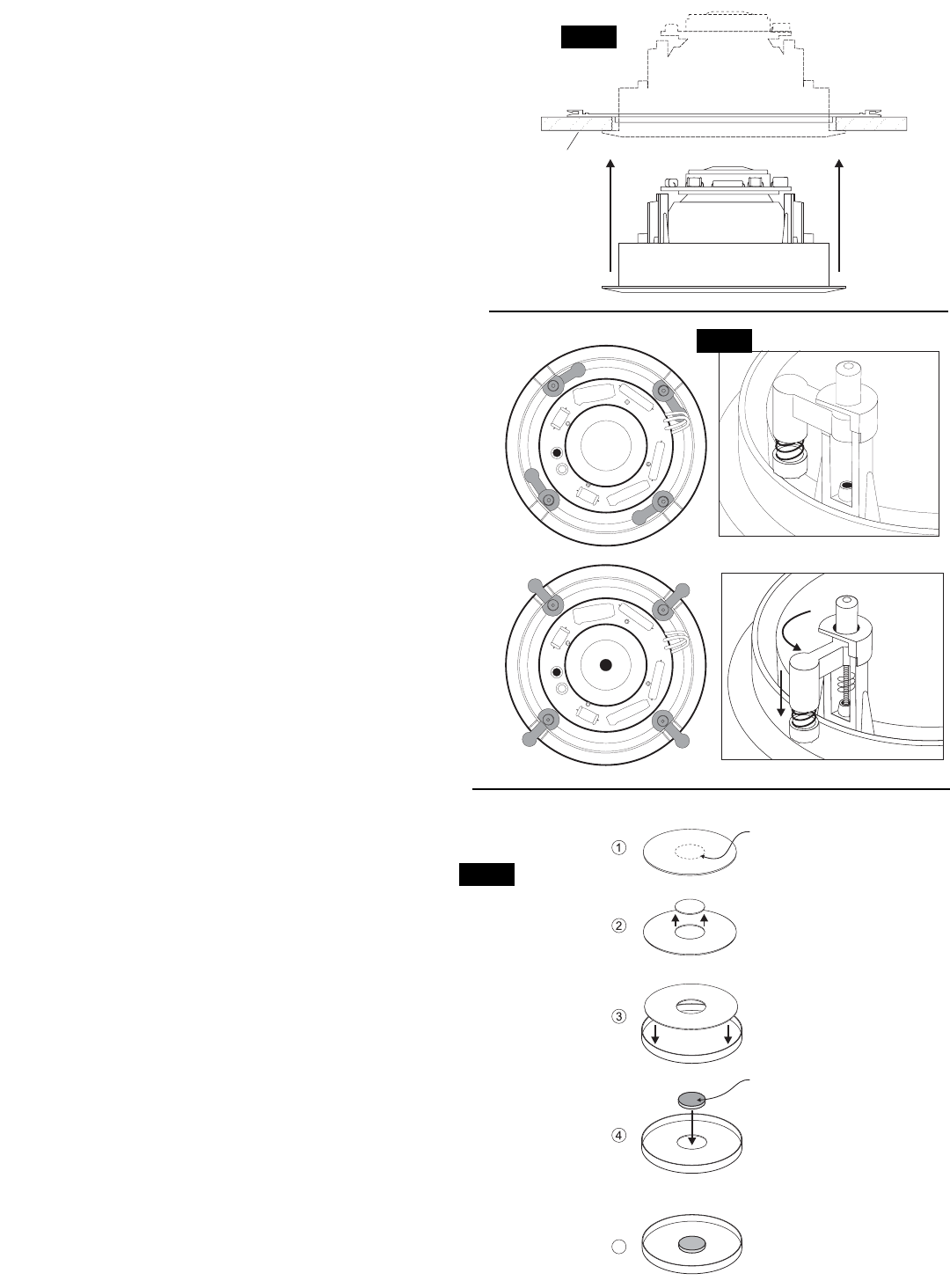

4. During the drywall phase, cut a hole around the bracket so

that the drywall surrounds the protruding lip of the mounting

bracket (iCB6 = 8 13/16” Dia., iCB8 = 10 1/4” Dia.). Once

installed, the lip of the speaker assembly will extend about 1/2

inch beyond the perimeter of the cutout to hide minor imper-

fections in the cutout (fig.3).

5. After the drywall is complete, connect the speaker wire to the

spring posts on the back of the speaker assembly, making sure

to observe correct polarity (see “Connections”).

6. The speaker assembly attaches to the bracket via four plas-

tic mounting clamps on the back of the speaker assembly that

swivel to “sandwich” the drywall between the speaker assem-

bly and the clamps (fig.4). First rotate the mounting clamps

inward so that the body of the speaker assembly can slide

through the mounting bracket. Exercise caution not to damage

the drivers.

7. Tighten the screws snugly, making sure to not over tighten,

as this may compromise the fit of the speaker assembly. The

use of power screwdrivers is not recommended. The gasket on

the drywall side of the speaker assembly lip reduces unwanted

vibrations against the drywall and will compress slightly to allow

the speaker assembly lip to rest flush against the ceiling. The

spring loaded mounting clamps provide tension once installed.

8. If the exposed area of the speaker assembly and grille are

to be painted after it’s mounted to the ceiling, install the paint

shield to protect the driver from overspray (see “Painting”).

Once painting is complete, remove the paint shield and set it

aside for use in Step #9.

9. The NHT in-ceiling speakers use an absorptive foam pad

(except the iC1) on the inside of the grille to shape the sound

radiation (fig.5). There is a circular section in the center of the

paint shield that serves as a template for attaching it. Punch

out the perforated circle. Place the paint shield (minus the cir-

cular section) on the inside of the metal grille, remove the

backer from the adhesive dot and attach the absorptive pad

onto the inside of the grille through the circular cutout.

10. A strip of butyl rubber is provided with this product.

Application of butyl rubber is not required, but can be used to

provide additional security when mounting the grill in place.

Cut a 1/4” long piece of butyl rubber from the end of the roll pro-

vided. Peel off the paper covering and roll the rubber between

your fingers until it makes a small cylinder. Make three of these

cylinders and place them in the groove before installing the grill

(fig.6).

11. Attach the metal grille by inserting it into the grooves in the

speaker assembly.

Drywall

fig.3

fig.4

Cut around

perforations

Remove

template

5

fig.5