3

the high-frequency driver is provided via an

integrated MOSFET circuit that actively

monitors and controls the power delivered

to the compression driver. There is also a

circuit breaker button on the rear control

panel designed to protect the woofer from

excessive power. The breaker “sees” the

amplifier signal being delivered to the

woofer and opens when the combination of

amperage and voltage exceeds the maxi-

mum rated power levels. The breaker

switch can be reset by pressing the button.

The rear control panel features both a

1/4˝ speaker jack and a Neutrik® Speakon®

connector, wired in parallel. The S500 cabi-

net is constructed using both multi-layered

plywood and pressure-injected structural

resin. The top and bottom sections both

have handles for easy movement and relo-

cation. There is an integrated pole-mount

on the bottom of the enclosure. In addition,

there are two, three-part cast-aluminum

handles on each side of the enclosure as

well as a full size, oval-punched, weather-

resistant steel grille.

phase plug. The result is frequency response

linearity and extension never before avail-

able for a product in this class. The S500 also

features a low-distortion, high-output horn

design developed to provide the correct

power response and phase alignment char-

acteristics at the crossover frequency. With

the resulting 75º x 65º dispersion pattern,

the S500 provides very open, natural sound

reproduction at extreme output levels.

The S500 produces deep bass through a

15-inch high-efficiency RCF® precision

woofer. The magnetic structure designed

for the woofer motor is responsible for the

system’s resulting high sensitivity of 100 dB

(1 watt@1 meter). More importantly, the

high-efficiency motor provides an extraordi-

nary amount of force that provides complete

control of the cone mass. This type of control

allows the woofer to deliver extended bass

response and to reach the mid-frequency

crossover point efficiently.

The S500 frequency response is linear

between 75 Hz and 20 kHz. Protection for

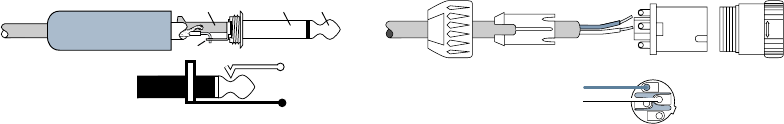

1/4” TS Connector

CONNECTIONS

The S500 has a 1/4˝ TS jack and a

Neutrik Speakon™ connector, wired in par-

allel. Use high-quality speaker cable as

recommended by the amplifier manufacturer.

The 1/4˝ TS jack uses the following

wiring standard:

Tip = Signal (+)

Sleeve = Ground (Shield)

SLEEVE

(SHIELD)

TIP (HOT)

TIPSLEEVE

TIP

SLEEVE

COLD

HOT

1+

1+

1–

1–

2–

2+

Neutrik Connector

The Speakon connector uses the follow-

ing wiring standard:

Pin 1+ = Signal (+)

Pin 1– = Ground (–)

SERVICE INFORMATION

Service outside the United States can be ob-

tained through local dealers or distributors.

If your S500 needs service, please follow

these instructions:

1. Call Tech Support at 1-800-258-6883,

8 am to 5 pm PST, to explain the problem

in detail. They will ask you all sorts of

impertinent questions in the hope of

sorting out the problem. If it appears

that the S500 needs repair, request an

RA (Return Authorization) number.

Warranty Service

If you think your loudspeaker has a

problem, please do everything you can to

confirm it before calling for service.

Repair

Service for the S500 is available only

from one of our authorized domestic ser-

vice stations or at the factory service center

located in Whitinsville, Massachusetts.