4

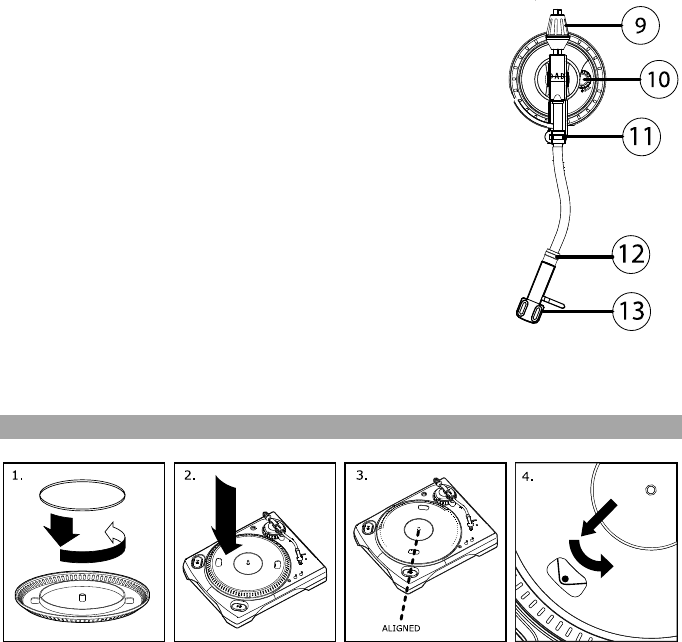

TONE ARM: Items 9 – 13 are all parts of the tonearm. Refer to the

TONEARM SETUP section for additional details on these controls.

9. Counter Weight and Scale Ring: The Counterweight is used

to balance the head shell and cartridge assembly so that the

proper amount of stylus pressure is applied to the record.

10. Anti-Skate Adjustment: This knob is used to compensate for

inward tracking forces. See TONEARM SETUP for more

details.

11. Arm Clip: This specially designed arm clip secures the tone

arm while at rest or when not in use. The arm clip has been

designed to remain in the up position while unlocked.

NOTE: When transporting the turntable, it is always

recommended that the headshell be removed and the arm clip

secured to prevent tonearm or turntable damage.

12. Tone Arm Lock Nut: This Aluminum nut is used to secure the

head shell and cartridge assembly to the tone arm tube. See

Cartridge Setup for more details.

13. Cartridge and Headshell: The cartridge is pre-mounted on a

standard headshell. The cartridge is user replaceable and compatible with a variety of

standard cartridges. Be sure to remove the clear plastic cover before operating the

turntable from the cartridge.

PLATTER SETUP

WARNING: Incorrect Platter setup can lead to poor turntable performance,

platter instability or permanent motor damage.

1. Start by placing the rubber drive belt around the inner bottom ring of the turntable platter.

This should come preinstalled, but check to make sure that it is not twisted or damaged.

2. Install the Platter on the center spindle and press it down firmly. Check to make sure that it

rotates uniformly and does not wobble excessively.

3. Rotate the platter so that the one of the holes is aligned with the Start Stop button on the

front corner of the turntable. The brass motor spindle should be visible through this hole.

4. Reach into the hole and pull the rubber drive belt off of the inner ring, and install it over the

motor spindle. Be careful not to twist the rubber drive belt during this step. Check to make

sure the platter rotates uniformly. If the drive belt is properly installed, there should be a

slight amount of tension that brings the platter to a stop after spinning it freely.