2

WIRE GAUGE AND QUALITY

PREPARING THE INSTALLATION LOCATION

Sonafill

Insulating the ceiling cavity

Retrofit

The total wire resistance should be less than 10% of the speaker

impedance. If using an 8 ohm speaker, your total wire resistance

should be no more than 0.8 ohms.

In simple terms, the extra resistance from the wire will have a very

negative affect on the sound quality of the speaker. The sound can be

less dynamic, definition of bass frequencies can be reduced, and in

extreme cases, the high frequencies can be attenuated. Amplifier

power is also wasted in the wire, reducing the maximum output level

of the system.

Please refer to the following chart when deciding on the appropriate

wire gauge for your installation.

Wire resistance in Ohms vs. length of cable run

Distance in Feet

50' 100' 150' 200' 250' 300'

.86

.65

.43

.27

.17

.11

18 gauge

16 gauge

14 gauge

12 gauge

10 gauge

20 gauge

1.73

1.30

.85

.54

.34

.22

2.59

1.94

1.28

.81

.51

.33

3.45

2.59

1.71

1.08

.68

.44

4.32

3.24

2.14

1.35

.85

.56

5.18

3.89

2.56

1.62

1.02

.67

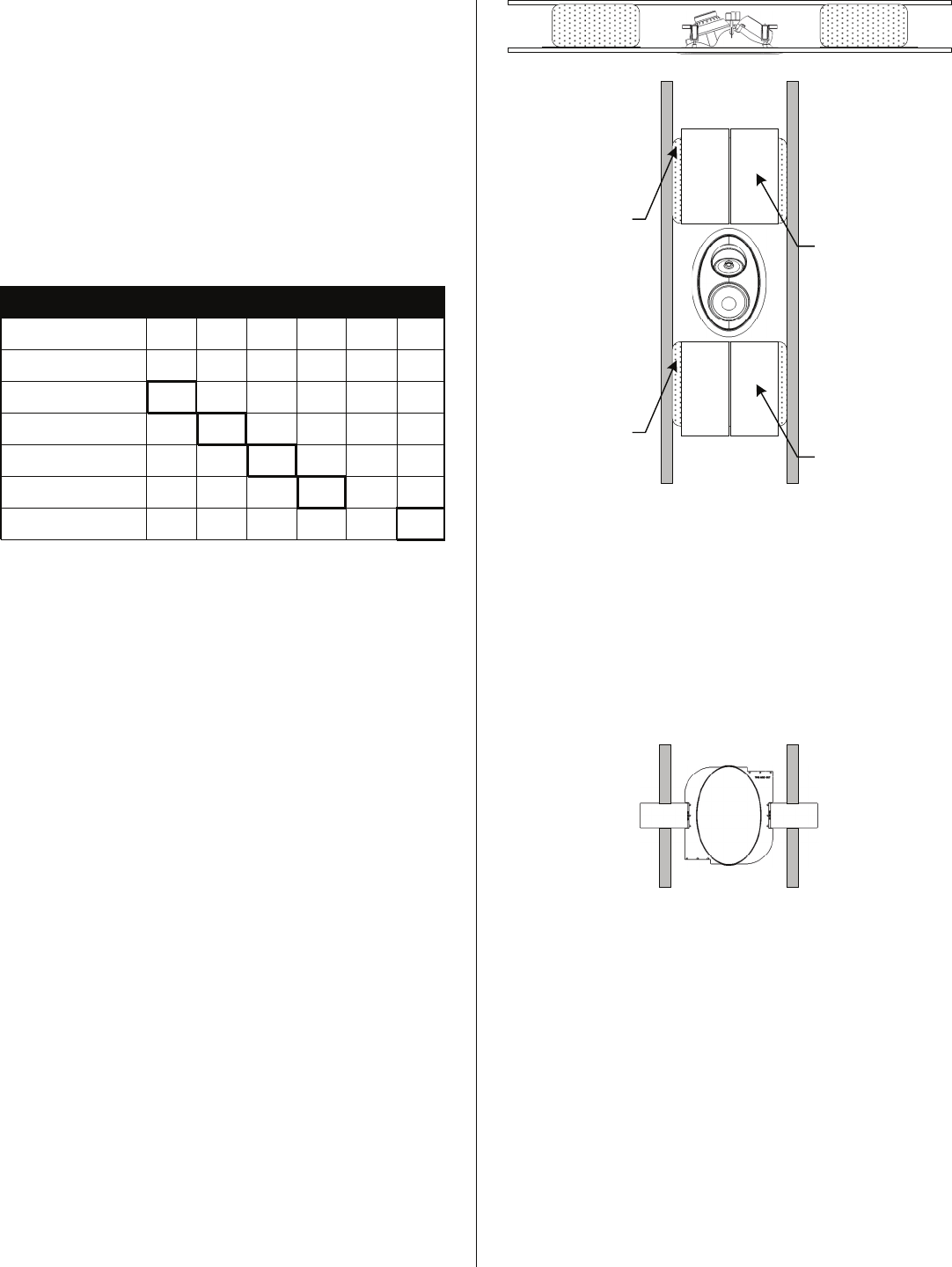

Speaker performance can be enhanced by insulating the cavity with

fiberglass insulation.

When installing speakers in a ceiling, it is best to lay a sheet of

unfaced fiberglass insulation over the back of the speaker.

To further improve the sound quality, install insulation in the bays

adjacent to the speaker location. This will reduce noise produced by

the unsupported drywall.

Sonafill is a retrofitable acoustical treatment for loudspeakers that

virtually eliminates the noise produced by resonating drywall and

dramatically improves mid-bass sound quality. Sonafill also reduces

room-to-room noise especially in multi-channel installations where

many speakers are installed.

The Sonafill system consists of two pillows and four tiles. Installation is

accomplished by first adhering the tiles to the inside of the cavity, then

stuffing the two pillows in place behind the tiles.

The Sonafill System

All Sonance speakers are designed to be relatively insensitive to

changes in enclosure volume. To achieve the ultimate performance

from the Ellipse LCR speaker, a section of the ceiling bay can be

sectioned off to form a back box. Building this enclosure will create a

dramatic improvement in the quality of bass response and power

handling.

Ideal Back box volume:

Ellipse 1.0 LCR 1.00 cubic feet (28.3 liters)

Ellipse 2.0 LCR 1.25 cubic feet (35.4 liters)

New Construction

Acoustic Pillow

Acoustic Pillow

Damping Tiles

Damping Tiles

Ellipse FlexBracket

The Ellipse LCR speaker features an integral FlexBar mounting

system for quick mounting into ceilings. The Ellipse FlexBracket is only

necessary in new construction installations when reserving a location

for the speaker is desired.

The FlexBracket will serve as a guide for the drywall installer when

cutting holes for in-ceiling speakers. The FlexBracket can be nailed,

screwed or stapled to the joists so that the hole is in the desired

location once the drywall is installed.

With the FlexBar system, the speaker can be installed directly into

existing ceilings. Once the hole is cut and the cable is run, the

speakers can be installed in a matter of seconds.

Once you have determined the area you would like to locate your

speakers, you will need to do an obstruction survey. Before you cut

the hole for the speaker, be certain no joist, conduit, pipe, heating

duct or air return will interfere with the speaker.

A cut out template is provided in the packaging of the speaker.

Position the template where the speaker is to be located and pencil an

outline on the ceiling. If you are unsure about obstructions drill a small

hole in the center of the circle and insert a coat hanger into the hole to

feel for possible obstructions. If no obstructions are found, proceed

with cutting the hole using a drywall saw and run the speaker wires.

®

®