Installation in

Existing Construction

IMPORTANT: Before you cut into any

wall, review the sections on running

wire and speaker placement.

1. When determining the location of the

speaker cutout keep in mind that the

mounting dogs will extend 3/4" beyond

the cutout. make sure that you do not

place the edge of the cutout directly

next to a ceiling joist. Locate the joists

using a stud sensor or hand-knocking.

2. Once you have determined a possible

position for the cutout, drill a 1/8” pilot

hole just barely through the ceiling

(1/2” to 5/8” deep in most homes)

about an inch below the center of your

proposed speaker location. BE VERY

CAREFUL NOT TO DRILL THROUGH

EXISTING WIRES, PIPES, OR STRUC-

TURE. IF YOU FEEL ANY EXTRA RESIS-

TANCE AS YOU ARE DRILLING, STOP.

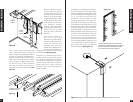

3. Cut a foot-long piece of coat hanger.

Bend the wire (creating a right angle)

leaving 4-1/8" at one end for the

CM5PR and 4/3/4" for the CM6PR (this

allows for the extra width of the mount-

ing dogs). Poke the “L-shaped” wire

into the pilot hole and turn it in a com-

plete circle and move it into the ceiling

cavity to make sure you have approxi-

mately 3-3/4" of depth. If the wires

movement is obstructed by anything, fill

the hole(s) with spackle and try another

location. (See Figure 14)

4. If the coat hanger moves freely in a com-

plete circle, hold the supplied template

up to the ceiling surface. Outline the cir-

cular cutout on the ceiling surface with a

pencil. Drill starting point with a 1/4" bit.

5. If you are cutting drywall use a

sheetrock or keyhole saw. Cut the hole

with the saw at a 45° angle. That way,

the drywall section can be replaced

cleanly if there is an unseen obstruction

behind the wall. BE VERY CAREFUL

NOT TO SAW THROUGH EXISTING

WIRES, PIPES, OR STRUCTURE. IF

YOU FEEL EXTRA RESISTANCE AS

YOU ARE CUTTING, STOP.

6. If you are cutting into a plaster ceiling,

use masking tape to outline your pen-

ciled circle and use a razor to score the

plaster down to the lath beneath. Then

use a chisel to remove all of the plaster

within the taped outline. To actually cut

the lathe, two methods are used profes-

sionally; sawing with a metal cutting

blade on a sabre saw is the quickest

and the riskiest. Sawing a lathe with a

sabre saw can easily vibrate plaster off

the ceiling in a completely distant loca-

tion creating more patchwork. If you

have the patience, use a pair of tin snips

to slowly nip away at the lath instead.

There is little risk with this method, it is

just time consuming.

14

Installation in Existing Construction

Figure 14

Installation

Fundamentals

Running the Speaker Wire in New

Construction

If you have doubts about whether you are

capable of installing a Niles ceiling mount

loudspeakers, consult a Niles dealer or

professional installer. They have special

tools, techniques, and experience to make

the impossible possible. The installer can

provide you with an estimate before any

work is done.

Scheduling and Preparation

Plan to schedule the speaker wiring after

the electrical wiring is finished. That way

you can avoid wire routes which could

potentially induce hum over the speaker

wire. The basic rules are:

• Never run speaker wire through the

same hole as an electrical cable.

• Never run speaker wire into the same

J-box as electrical cable.

• Avoid running the speaker wire beside

the electrical cable. Keep your speaker

cable at a distance of at least 18"-22"

from any electrical power cable.

Side-by-side wiring is unavoidable in par-

ticular spots in every house, just move the

speaker wire route away as soon as possi-

ble. If construction forces a side by side

run for more than ten feet, install metal

conduit or shielded speaker wire. Low-

voltage wires such as doorbells, inter-

coms, telephone, security, or television

cannot cause interference or hum on your

speaker wires, so you can safely run all of

them at the same time, through the same

holes, side-by-side.

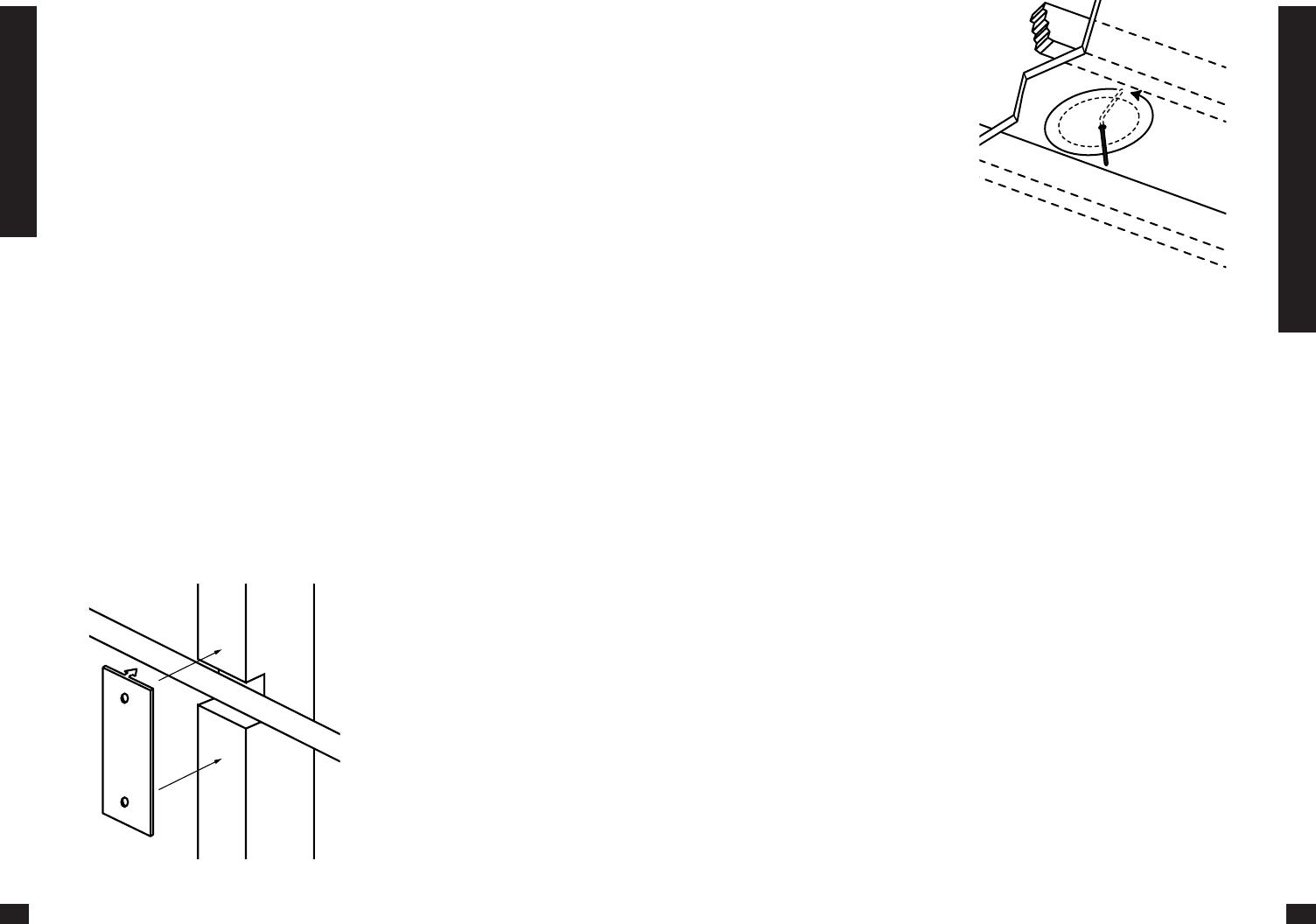

Before you drill any holes, mount the

speaker brackets in the desired speaker

locations and mount p-rings or open

backed J-boxes where the in-wall volume

controls and stereo equipment will be.

Safety First!

Wear gloves, safety goggles and head pro-

tection when drilling. Avoid nails, they ruin

bits and they can create injury. Pay particu-

lar care when using “hole-hogs” and other

powerful electric drills; the torque of the

drill when suddenly stopped by a nail can

break the wrist of a strong man.

Drilling

Use a bit that is large enough for the wires

you plan to run. An auger bit is the pre-

ferred bit for rough-in wiring. It will actu-

ally pull itself through the wood, so that

the drill motor, not you, does most of the

work. You may be drilling a lot of holes,

so this is an important consideration.

Always drill the holes in the center of the

stud. If you have to notch the stud or drill

the hole closer than one inch from the

edge of the stud, protect the wire with a

nail plate (See Figure 7).

When drilling holes in ceiling joists drill

in the center of the joists and try to locate

the hole near the end of the joist. DO

NOT drill through a “gluelam” or any

load bearing beam without the direction

of your contractor.

9

Installation Fundamentals

Figure 7