4 5

PERFORMANCE

INSTALLATION

KM625.2

6 (16)

1 (2.5)

Titanium

4

225 (75)

88

35-21k

5 1/8 (13)

2 7/8 (7.2)

1 15/16 (4.8)

18, 4000

12, 4000

Yes

Performance

Model:

Woofer Size, in (cm)

Tweeter Size, in (cm)

Dome Material

Nominal Impedance [Zn], ohm

Power Handling Watts, Peak (RMS)

Sensitivity [SPLo], dB @ 1W, 1m

Effective Frequency Range, Hz

Woofer Mounting Hole Diameter, in (cm)

Woofer Mounting Depth w/o Crossover, in (cm)

Flush Mounting Tweeter Hole Diameter, in (cm)

High Pass, dB, at Frequency, Hz

Low Pass, dB, at Frequency, Hz

Bolt-Thru Grilles

Kicker Marine speakers use the highest level of magnetic shielding available to minimize compass and gauge deviation in your dash.

Kicker Marine speakers meet or exceed industry standards for environmental humidity and corrosion,

and for material degradation due to UV exposure.

KMCOMPONENTSYSTEM

Crossover Cover

Figure 5

Crossover mounted to

the KM Component

Woofer’s Back Plate

Figure 4

Slot

KM620.2

6 (16)

3/4 (2.0)

Titanium

4

195 (65)

88

35-21k

5 1/8 (13)

2 7/8 (7.2)

1 9/16 (4.0)

18, 4000

12, 4000

Yes

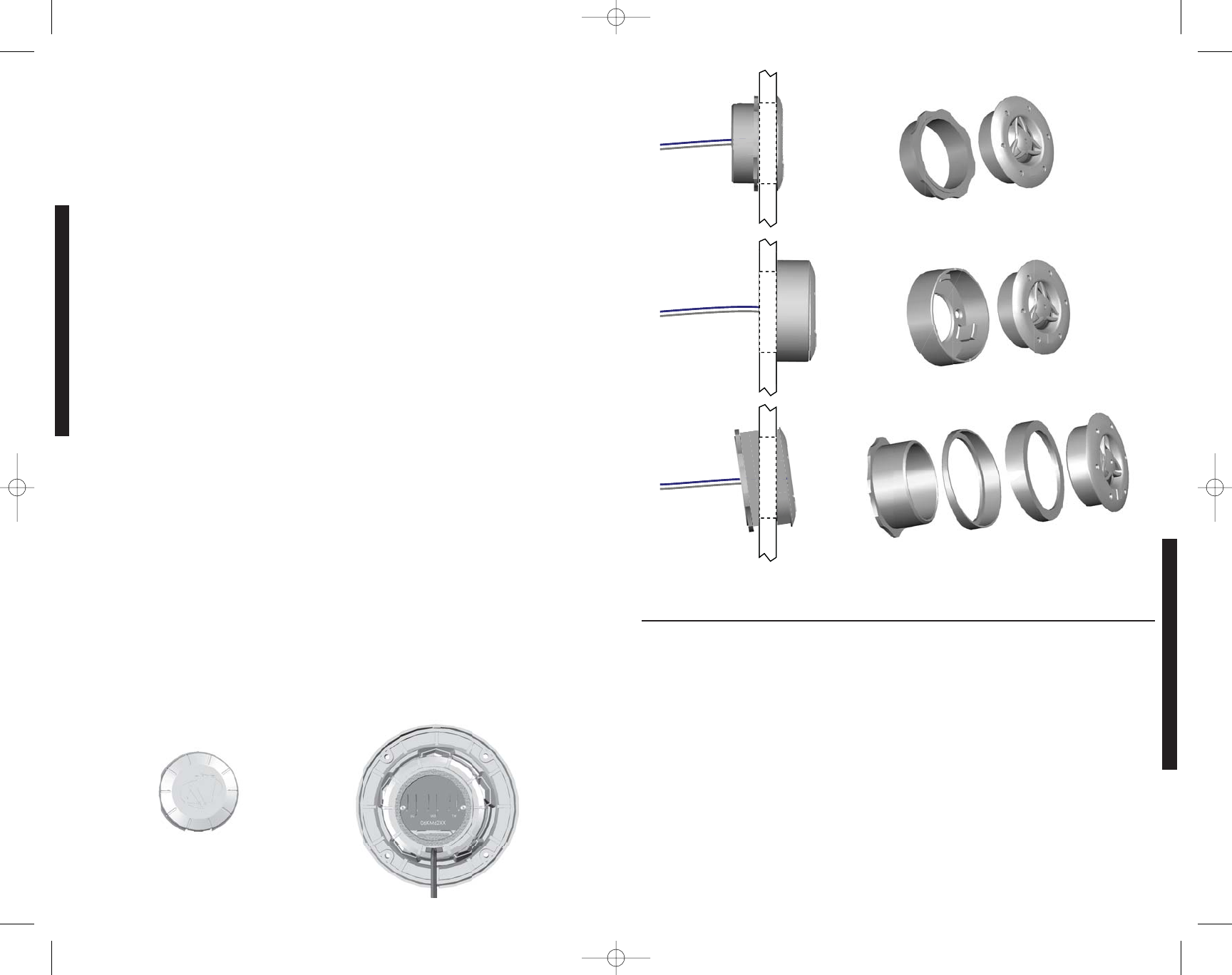

TweeterMounting

The tweeter can be mounted one of three ways: flush, surface and angled mounting. For

flush mounting applications, please refer to the illustration in Figure 5. Choose a flat

location on the panel with space behind the panel to allow room for the mounting nut. After

checking the clearances, cut the appropriate mounting hole diameter in the panel (see the

chart below). Place the shorter mounting nut behind the panel. Feed the wire through the

hole in the panel and the mounting nut. Mount the tweeter by screwing the mounting nut

onto the tweeter.

For surface mounting applications use the surface mount cup as a template and pre-drill

two 7/64” (2.5mm) screw holes for attaching the mounting cup to the panel, and a 5/16”

(8mm) hole for the wires. Two #8 flathead stainless steel sheet metal screws are supplied to

attach the mounting cup to the panel. Position the tweeter over the mounting cup and press

it into position. See Figure 5.

For angled mounting applications choose a flat location on the panel with space behind the

panel to allow room for the mounting nut and back angle ring. After checking the

clearances, cut the appropriate mounting hole diameter in the panel (see the chart below).

Place the front angle ring (does not fit through the longer tweeter mounting nut) in front of

the panel. Then place the wire and tweeter through the front angle ring and into the panel.

Next place the wire through the back angle ring (fits through the longer tweeter mounting

nut), place the back angle ring over the rear of the tweeter, and line-up the narrow part of

the front angle ring for the preferred angle of operation. Place the wire through the longer

tweeter mounting nut and loosely tighten the mounting nut around the tweeter. Rotate all the

parts in unison until the tweeter is angled in the desired direction. Secure the assembly by

tightening the tweeter mounting nut. See Figure 5.

Wiring

Carefully place the speaker wire in a location that is clear of standing water and moving

components of the vessel. For reference, the Blue wire is Positive and the Silver wire is

Negative. Mount the crossover to the woofer’s back plate with the enclosed phillips-head

M3 stainless steel machined screws, or mount the crossover remotely in a location free and

clear of standing water. The locking crossover cover with water resistant gasket is

removable for wiring installation; it helps prevent terminal corrosion and electrical shorting.

The positive and negative gold plated terminals are of different sizes and correspond to the

appropriate gold plated positive and negative wire connectors. Take off the crossover cover,

and connect the wire from the woofer to the “WF” terminal and the wire from the tweeter to

the “TW” terminal. Connect the supplied 15 feet (4.5m) of wire to “IN” terminal in the

crossover. Carefully route the wires through the slot between the crossover and crossover

cover, and snap the crossover cover back on the crossover. Connect the other end of the

heavy gauge wire to your amplifier in accordance with its owner's manual. See Figure 4.

Flush Mount

Surface Mount

Angled Mount

Shorter Mounting Nut

Surface Mount Cup

Longer Mounting Nut

Back Angle Ring

Front Angle Ring

Panel

Panel

Panel

2006 KM Component b01.qxp 2/8/2006 5:35 PM Page 3