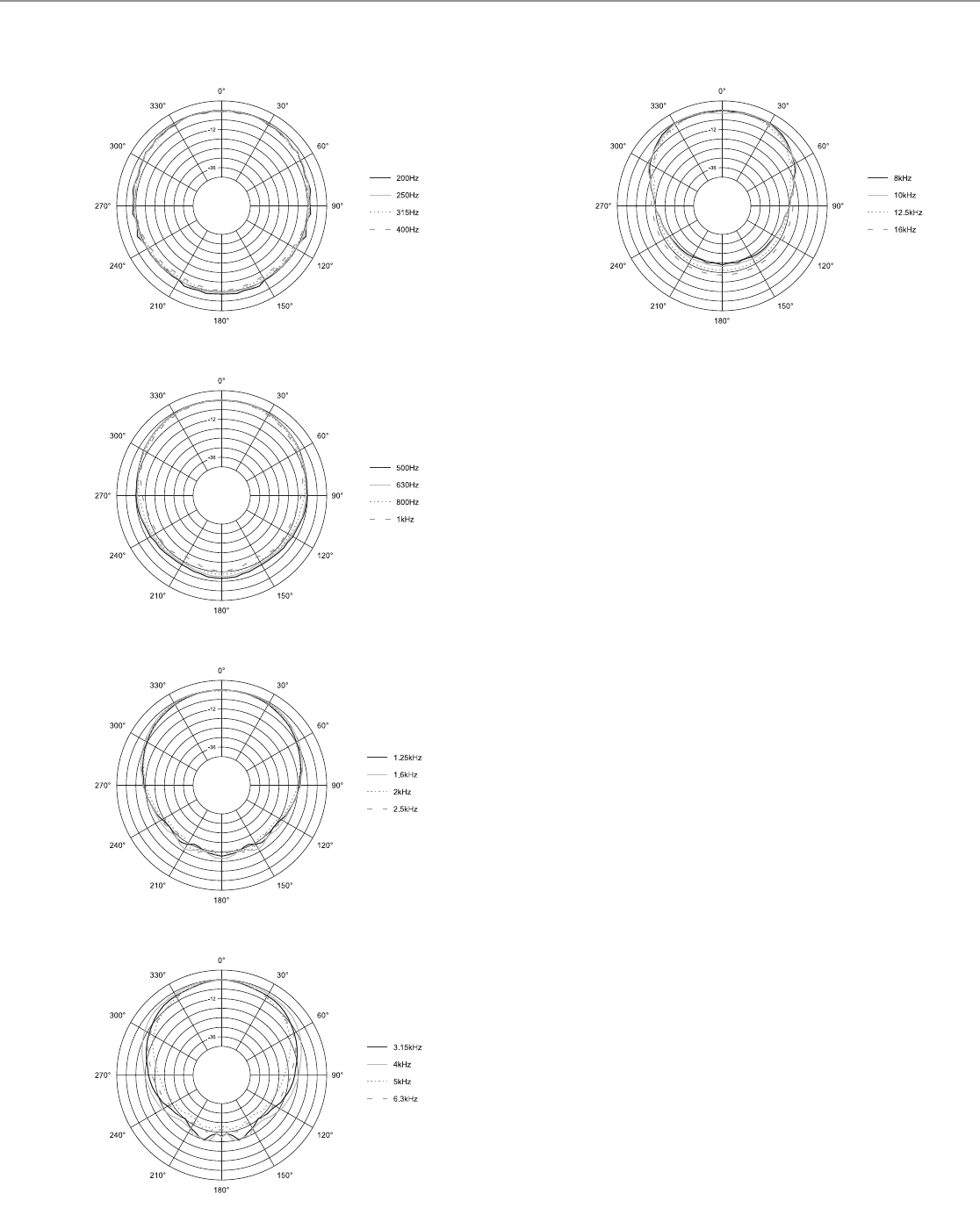

Horizontal 1/3 Octave Polars

Architectural Specifications:

The loudspeaker shall consist of a 250 mm (10 in) low frequency

transducer, a coaxial 125 mm (5 in) mid frequency transducer with a

25 mm (1 in) compression driver, and frequency dividing network. The

low frequency driver’s voice coil shall be 50 mm (2 in) in diameter and

the mid frequency driver’s voice coil shall be 25 mm (1 in) in diameter.

Performance specifications of a typical unit shall be as follows:

Usable frequency response shall extend from 38 Hz to 17 kHz (10 dB

below rated sensitivity, half-space, no external equalization). Rated

power shall be at least 500 watts continuous program power for 100

continuous hours duration (defined as 3 dB above a test signal of fil-

tered random pink noise conforming to IEC268-5). Measured sensitivity

shall be at least 93 dB-SPL (at 1m [3.3 ft] with 2.83V input, avg. 100 Hz

to 10 kHz).

The input shall be switchable for use either at nominal 4 ohms, or

on a 70.7V or 100V distributed speaker line via built-in transformer.

Selectable taps shall nominally be 150W, 75W, or 38W on a 70.7V or

100V distributed line, plus 19W on 70.7V line only.

The system shall be protected against damage from occasional over-

powering via full range limiting, which shall be inaudible during

activation. The coaxial mid-high driver shall be horn loaded to cover

120 degrees horizontal by 110 degrees vertical with a high degree of

accuracy.

The cabinet shall be molded High Impact PolyStyrene (HIPS) with

ten percent glass fill, and a 5 mm internal foamed polyurethane

secondary mold. The grille shall be backed by multi-layer foam and be

secured via screws to keep it in place when facing downward. The

cabinet and grille shall be paintable.

The low frequency transducer shall have a neodymium magnet, a

cone of woven fiberglass and Kevlar

®

and butyl rubber surround, with

the frame protected from direct weather exposure. The mid frequency

transducer element of the coaxial mid-high driver shall have an

anodized aluminum cone with an EPDM rubber (a Terpolymer of

Ethylene and Propylene) surround, with the frame protected from

direct weather exposure. The compression driver shall be constructed

with a titanium diaphragm for weather resistance. The coaxial mid-high

driver shall be protected with a secondary acoustically transparent

screen. The system shall withstand Mil Spec 810 testing with specified

durations with no effect on its acoustical performance or structural

integrity; salt spray (method 509.3), temperature (method 501.3 and

502.3), humidity (method 507.3) and ultraviolet (method 505.3).

Further, it shall pass Mil-Std-202F (method 101D) for salt spray. They

system shall have an IEC 529 splashproof rating of IP-X5.

For theft deterrence, the installation access area shall be hidden

behind a snap-out cover on the front grille. The included ball mecha-

nism shall be internal to the cabinet. The cabinet shall have ten (10)

6 mm mounting points including 3 on each side and 3 on top and

bottom and an accessory U-bracket shall be available. The grille logo

shall be rotatable for proper orientation with loudspeaker mounted

horizontally or vertically.

The external wiring connectors shall be screw-down terminals.

Overall cabinet dimensions shall be no greater than 593 high x

372 mm wide x 345 mm deep (23.3 x 14.6 x 13.5 in) and shall weigh

no more than 18.9 kg (42 lb). The finish shall be lightly textured black

or white.

The system shall be the JBL Model Control 30 (or Control 30-WH)

with included InvisiBall

®

(mounting system).

74947_JBL_Ctrl30 6/28/07 9:28 AM Page 3