CONTROL 328C/CT SYSTEM ASSEMBLY

7

JBL Professional Control 300 Series

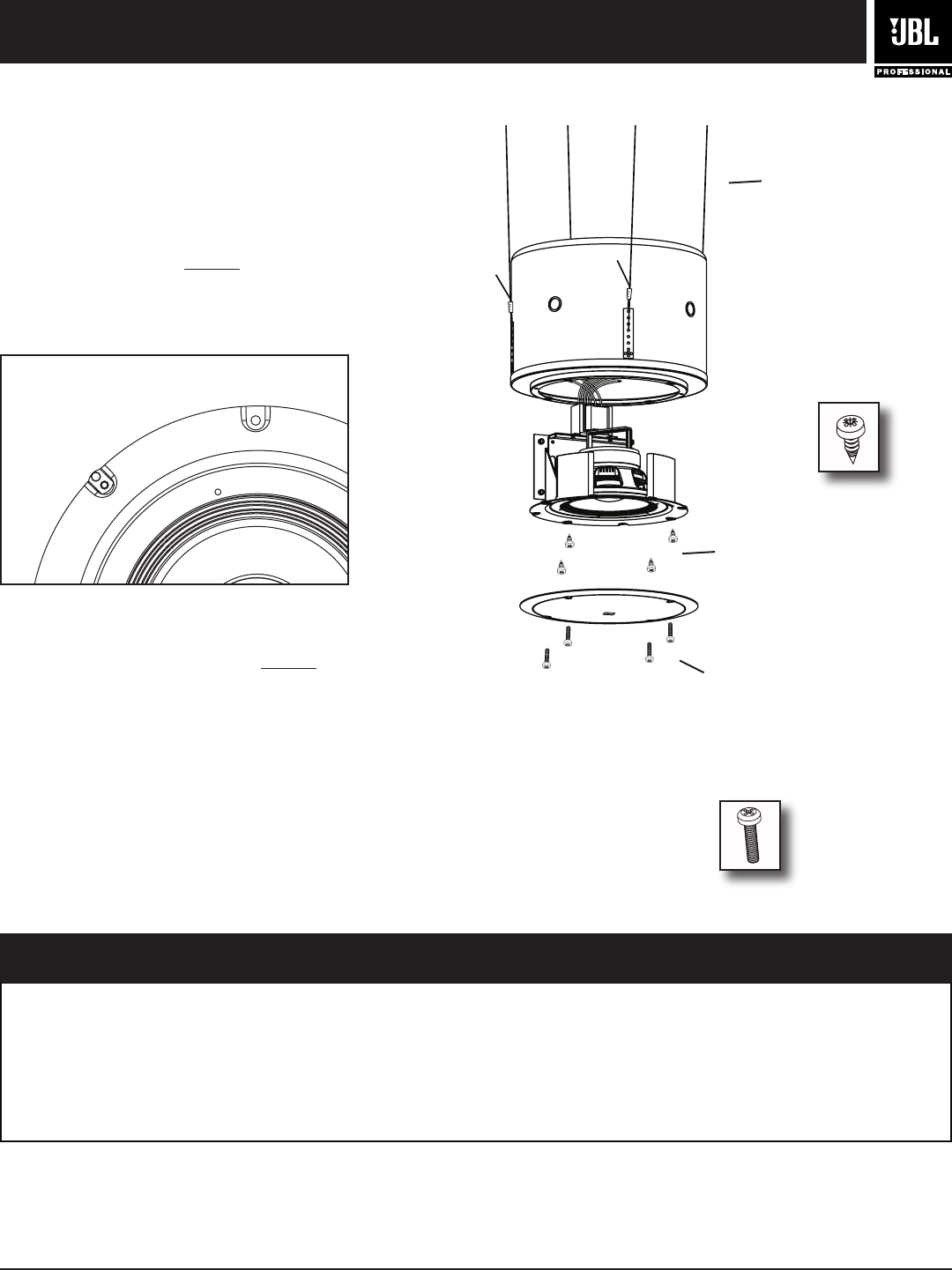

Ceiling Preparation - Cut a 12.2 inch (310 mm)

diameter hole in the ceiling to allow sufficient room for the

loudspeaker baffle.

Assembling the Control 328C/CT into the Back Can

- After inserting the Control 328C/CT into the back can,

align the mouting holes without weld nuts to the holes with

clip nuts on the back can. These are the mounting points

that will be used to secure the Control 328 baffle and driver

to the backcan.

Next, using 4 pcs - #10 x 0.75 in (19 mm) sheet metal

screw, attaching the baffle / driver to the back can. Be

sure to match the mouting holes without weld nuts to clip

nuts on back can.

Finally, using 4 pcs - M4 x 38 mm powder coated machine

screws, attach the metal grille to the baffle. Be sure to

match the grille mouting holes to the weld nuts on the

baffle assembly.

4 pcs - #10 x 0.75 in (19 mm)

sheet metal screw for attaching

the baffle / driver to the back

can. Match to clip nuts on

back can. (Included with MTC-

300BB8. )

4 pcs - M4 x 38 mm powder

coated machine screws for

attaching the metal grille to

the baffle. (Included with JBL

Professional grilles.)

Weld nut

mount point

Non-Weld nut

mount point

IMPORTANT!

When installing the

MTC-300BB8 with a

Control 328C/CT,

see “Securing Speaker

Assembly to the Building

Structure” details below.

The backcan must be secured to the building structure by qualified personnel in accordance with safe

installation practices. Use suspension materials, connection fixturing, and methods that are appropriate for

the building structure and installation conditions. Employ a minimum 5:1 safety factor for each suspension

point, or higher if required by code. For MTC-300BB8 with a Control 328C/CT a 5:1 safety factor requires

that each suspension point be rated to support a minimum of 57 kg (125 lbs).

IMPORTANT: SECURING SPEAKER ASSEMBLY TO THE BUILDING STRUCTURE