ver 1.0

8

88

8

~ÄëçäìíÉ=ÑáÇÉäáí

ó

3.3 Vibration-free Cabinet

The cabinet was designed for aesthetics, but with an obsession to sonic

quality, vibration control, structural strength and rigidity.

In some parts of the cabinet where vibration would have been the

greatest, 1½ inches (36mm) of multi-layer bonded MDF was used to

provide damping, structural integrity and a rigid platform for the drivers to

be located. Extensive bracing was carefully incorporated using 12mm

slabs of MDF to eliminate cabinet flex and panel resonance.

Incidentally, MDF was chosen as the material of choice for its damping

properties and its consistency in hardness, density and rigidity. It would

actually have been cheaper and easier to make the cabinet of solid

wood, but that would have been a compromise.

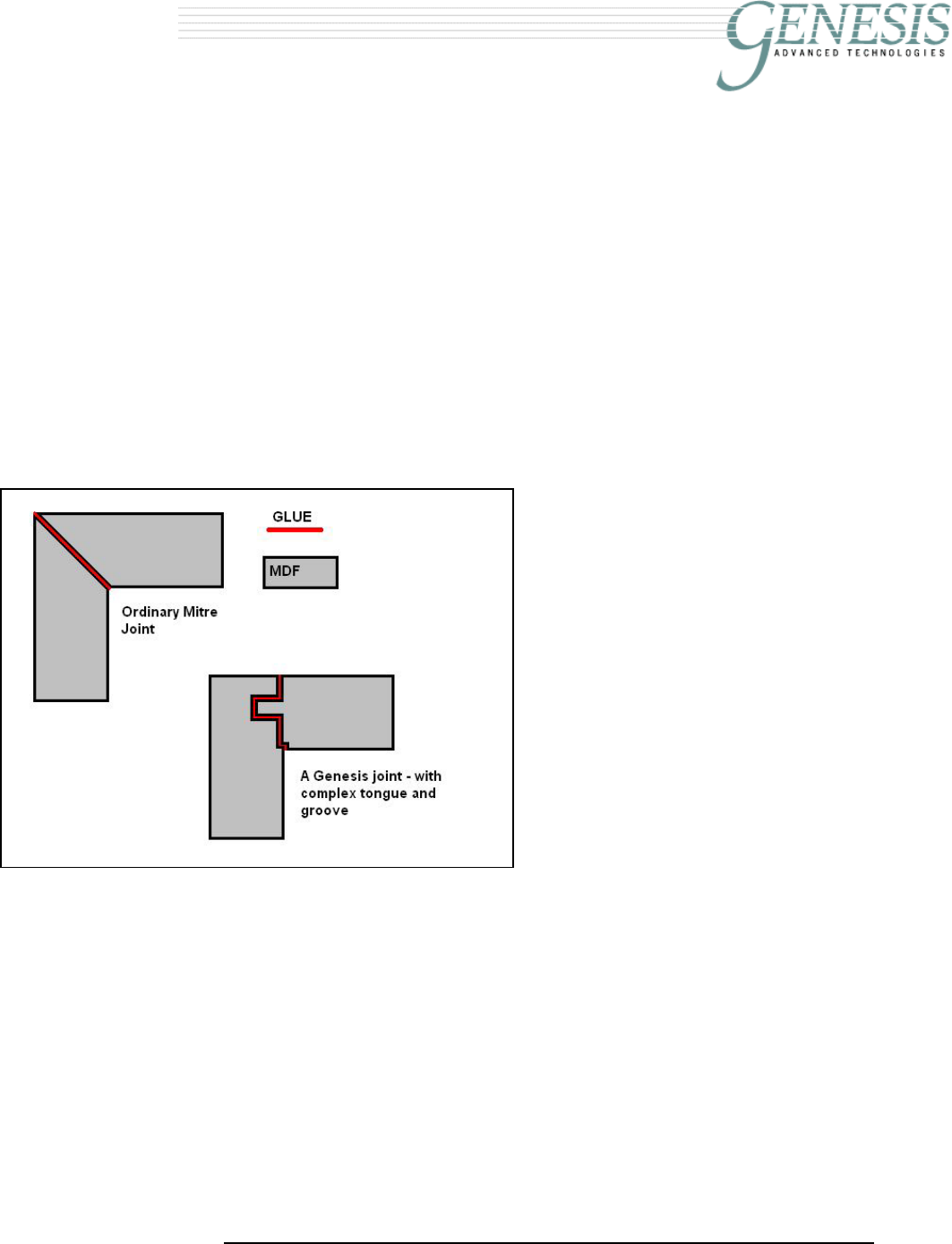

Genesis designed a unique tongue

and groove joint in order to improve

the structural rigidity of the cabinet.

Crystalline glue the dissolves into the

mdf was chosen to ensure that the

interfaces between two panel pieces

becomes as one. This results in the

entire enclosure behaving as a single

unit, with seemingly no discontinuity in

material.

This results in a joint so strong that

when you try to rip the joint apart, it

isn’t the joint that would break. The

mdf would break apart first.