The DL10X passes AES2-1984/ANSI S4.26-

1984 with the following values:

Z

MIN

= 6.0 ohms at 350 Hz

P

E

(max) = 300 watts

Test voltage = 42.5 volts rms,

95.0 volts peak

(+6 dB)

Selected decade = 50-500 Hz

RESPONSE IN STANDARD BAFFLE

AES requires a large, planar baffle for this test,

WHICH IS INTENDED TO SHOW SMOOTH-

NESS AND OFF-AXIS RESPONSE, NOT

BASS RESPONSE. This has proven to be

inconvenient and prohibitive, due to its size.

Here, we have chosen our lab-standard, low-

diffraction, 12-cubic-foot test enclosure, which

will demonstrate the same characteristics as

the AES standard baffle (see Figure 2). A

smoothed, swept-sine-wave input is used for

this measurement to provide a more informa-

tive curve to the end user.

TYPICAL ENCLOSURES

The most extended bass, lowest distortion and

best control is usually realized in properly de-

signed vented enclosures. In such designs, the

vent, or port, actually provides the lowest oc-

tave of output. The vent is driven to full acoustic

output by a relatively small motion of the speaker

cone itself, acting through the air contained

within the enclosure. The excursion of the DL10X

at these frequencies is much reduced com-

pared to sealed or open-back enclosures, di-

rectly reducing harmonic distortion and the

possibility of speaker bottoming. Used as a

midbass speaker, horn loading may be desir-

able for the DL10X. Usable frequency re-

sponse in a horn-type enclosure can extend

from 100 to 4,000 Hz. Please note, however,

that in a horn-loaded system, the actual perfor-

mance greatly depends on the design of the

horn enclosure. Factors such as flair rate,

mouth size, and rear chamber volume play

critical roles in the performance of any horn-

loaded system.

Normally Tuned Enclosures

The DL10X in a 1.0-cubic-foot enclosure tuned

to 75 Hz has essentially flat response to 90 Hz

(See Figure 9).

Figure 11 shows the maximum predicted output

level, taking power handling and displacement

limitations into account.

SUBPASSBAND SPEAKER PROTECTION

Below the enclosure tuning frequency, cone

excursion increases rapidly. Since acoustic

output is also falling rapidly, there is no utility in

driving the system with signals much below

tuning frequency. While such signals may be in

the program material, they are often extrane-

ous, such as a dropped microphone. The

Electro-Voice EX-24, XEQ-2 and XEQ-3 elec-

tronic crossover/equalizers can provide sub-

passband protection. The 3-dB-down points

are 30 Hz (EX-24 and XEQ-2) and 16 Hz or 32

Hz (XEQ-3).

Other high-pass filters are available, and one-

third-octave equalizers can also be effective at

providing the required protection.

MOUNTING

The DL10X may be front- or rear-mounted

and materials available.

Great care was taken in the selection of dia-

phragm materials and construction to ensure

smooth, musical upper-bass reproduction. The

cone has a moisture-repellent treatment, allow-

ing it to be used in harsh and humid conditions.

(Do not expose the cone to direct water or

sunlight.)

The DL10X is a true high-fidelity woofer in every

sense, being capable of high output, low distor-

tion, and solid bass response.

DIRECTIONAL CHARACTERISTICS

The directional characteristics of the DL10X in

a 2.0-cubic-foot vented enclosure were mea-

sured in Electro-Voice’s large anechoic cham-

ber. The test signal was one-third-octave fil-

tered pink noise centered at the frequencies

indicated. A full spherical measurement sys-

tem, which is completely compatible with the

AcoustaCADD

TM

computer-aided design pro-

gram, was used. All directional information was

measured at 20 feet. Figure 8 illustrates the

horizontal and vertical polar responses. Figure 6

shows the horizontal and vertical beamwidths.

Beamwidth is the angle at which the horizontal

and vertical polar responses have decreased in

level by 6 dB when compared to the axial

frequency response. Figure 7 illustrates the

total directivity of the DL10X. The directivity

factor R

θ

(Q) is the relative value, at a point, of

the DL10X when compared to an ideal spheri-

cal response. The directivity index, D

i

, is calcu-

lated by the formula: D

i

= 10 log

10

R

θ

.

TYPICAL AMPLIFIER SIZE

300-600 watts per woofer is the optimal ampli-

fier size. Amplifiers of this size will allow maxi-

mum output with minimal risk of speaker dam-

age when properly used. Smaller amplifiers

can also be used with excellent results—the full

capabilities of the speaker will simply not be

used.

POWER-HANDLING TEST

Electro-Voice components and systems are

manufactured to exacting standards, ensuring

they will hold up, not only through the most

rigorous of power tests, but also through contin-

ued use in arduous, real-life conditions. Two

main test specifications are used: the “AES

Recommended Practice for Specification of

Loudspeaker Components Used in Professional

Audio and Sound Reinforcement” (AES2-1984/

ANSI S4.26-1984) and the “EIA Loudspeaker

Power Rating Full Range” (ANSI/EIA RS-426-A

1980). Both of these specifications use noise

spectrums which mimic typical music and test

the thermal and mechanical capabilities of the

components. Electro-Voice will support relevant

additional standards as and when they become

available. Extreme, in-house power tests, which

push the performance boundaries of the com-

ponents, are also performed and passed to

ensure years of trouble-free service.

Specifically, the DL10X passes ANSI/EIA

RS-426-A 1980 with the following values:

R

SR

= 6.9 ohms (1.15 x R

E

)

P

E

(max) = 300 watts

Test voltage = 45.5 volts rms,

91.0 volts peak

(+6 dB)

_______________________

4. Teflon

®

is a registered trademark of DuPont.

Dimensions (see Figure 10),

Outer Diameter:

266 mm (10.48 in.)

Overall Depth:

120 mm (4.7 in.)

Net Weight:

8.6 kg (19.0 lb)

Shipping Weight:

9.5 kg (21.0 lb)

DESCRIPTION

The DL10X low/mid-frequency reproducer is a

10-inch, 8-ohm driver designed for professional

high-level, high-fidelity monitoring and sound

reinforcement. At the heart of this speaker is a

carefully engineered drive system. Its design

assures linear, low-distortion output, high power

capability and efficient heat transfer.

Incorporated into the design are three exclu-

sive Electro-Voice innovations. PROTEF

TM

coat-

ing (U.S. patent #4,547,632), a Teflon

®

-based

coating, is applied to the inside diameter of the

top plate.

4

Occasional violent power peaks of

several seconds may expand a transducer’s

voice coil into contact with the top plate, caus-

ing failure. PROTEF provides protection against

such failure. The coating lubricates any rubbing

contact and provides electrical insulation be-

tween the coil and the steel top plate. The

Thermo Inductive Ring (TIR

TM

) and Flux De-

modulation Device (FDD

TM

), also included in

the DL10X design, are aluminum castings fas-

tened to the pole of the magnet. They provide a

shorted turn to control inductance and provide

a major heat transfer path from the voice coil,

which improves power handling and reduces

thermal dynamic-range compression.

The voice coil itself is constructed of edge-

wound rectangular aluminum wire, mounted on

a rugged laminated polyimide former. The com-

plete assembly is low in mass and is fabricated

using the most advanced epoxies, insulations

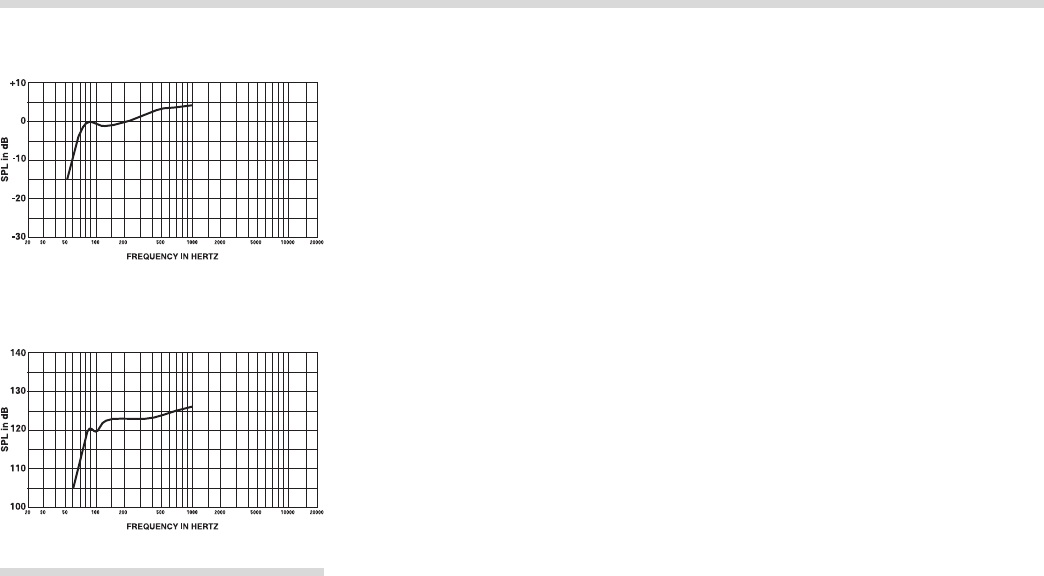

FIGURE 10 — Predicted Low-Frequency

Response in a Typical

Enclosure (1.0 ft

3

tuned to 75 Hz)

FIGURE 11 — Maximum SPL at 1 Meter in a

Typical Enclosure

(1.0 ft

3

tuned to 75 Hz)