duce the chance of breaking the plaster. Test fit the speaker in

the hole, the speaker should fit loosely and the speaker frame

should cover the edges of the hole. Repeat these steps for the

other speaker

.

5) Speaker Cable

Don’t compromise sound quality by using thin, inexpensive

speaker wire, we recommend using a high quality oxygen free

copper speaker cable. For runs less than 50 feet we recom-

mend 16 gauge cable, and for longer runs we recommend

14 gauge or larger cable. Most municipalities require the use

of CL2 rated speaker cable for installation in walls and ceilings.

Leave enough speaker cable so you can stand comfortably on

the floor or ladder while connecting the speaker cable to the

speakers.

6) Speaker Connection

Remove about 8" of the cable jacket to expose the inner conduc-

tors. Strip 1/4" of insulation from each conductor and connect to

the speaker terminals. When connecting the wires to the speak-

ers, be sure to observe proper polarity. Most CL2 rated speaker

cable will have red and black conductors so you will connect the

red wire to the red speaker terminal and the black wire to the

black speaker terminal.

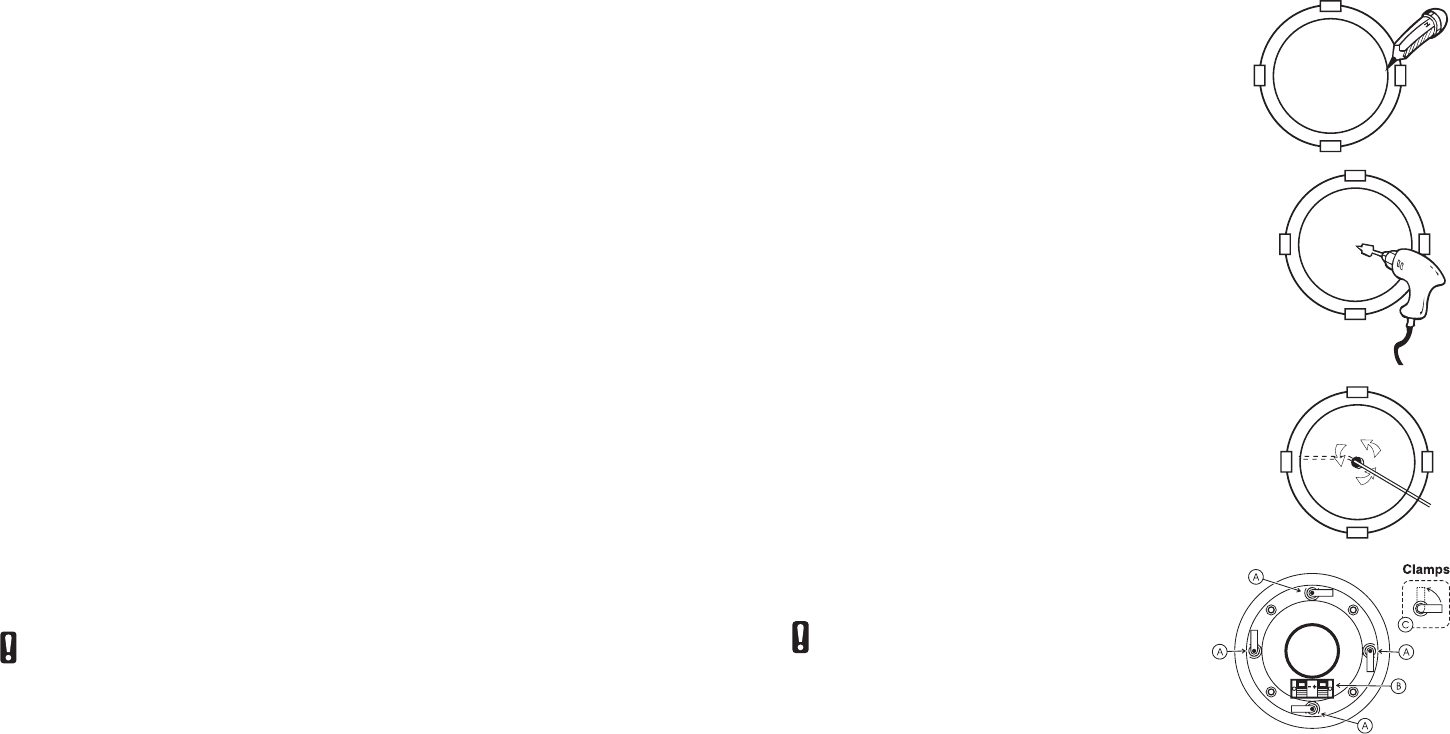

7) Final Installation

To install the speakers into the ceiling, remove the grills, this

will give you access to the mounting screws. Turn the mounting

clamps so they are positioned as in the illustration, this will allow

the speakers to clear the hole for installation. Insert the speaker

into the hole, and tighten the mounting screws. As you

turn each screw, the mounting clamps will rotate outward to

engage ceiling material.

CAUTION: Do Not Over-Tighten the Clamps. Too much

torque may snap off the lug and the speaker will not seat

securely. A snug fit is all that is necessary to assure proper

performance.

8) Painting Speakers

If you choose to paint the speaker grill and/or frame we

have provided a “Paint Masking Template” to cover the woofer/tweeter assembly and help

prevent possible damage. Do not try to paint the frame and grill assembly together, the

grill should always be painted separately.

Do not apply heavy coats of paint that might block the perforations in the grill.

9) Troubleshooting

Should your speakers not work properly, check the following:

No sound from speakers:

● Most stereo receivers have an A/B speaker selector switch. Make certain that

this switch is in the proper position.

● Mute feature is activated.

One speaker is playing while the other is not:

● Check the balance control on the receiver. Make sure it is centered.

●

Loose connection at either the receiver or the speaker. Double check connections.

● Bad speaker cable. Replace suspect speaker cable.

Receiver cuts on and off:

● This could be caused by a short circuit between the positive and negative leads.

Check the connections at the back of the receiver, and then at the speaker; make

sure that no strands of wire from one connector are touching the other connector.

Congratulations on the purchase of your Dayton Audio

®

CS625C Contractor Series Ceiling Speakers.

These speakers were manufactured with high quality components and engineered to deliver top quality

sound performance.

● Contemporary low profile grill design

● Long-throw polypropylene cone woofers with rubber surround

● Coaxially mounted 1" silk dome tweeter

● 12 dB/octave optimized crossover

Please read these instructions completely before you begin your installation.

1) Parts Inventory

Your speaker kit should include the following:

● 1 pair of Dayton Audio Contractor Series Ceiling Speakers with Grills

● 1 speaker installation / paint masking template

2) Installation Tools

The Dayton Audio speakers can be installed with the following simple tools:

● Pencil ● #2 Phillips screwdriver

● Masking tape ● Wire cutters & wire stripper/crimp tool

● Drill & drill bits ● Stud finder**

● Utility knife or wallboard saw*

* Recommended for use if installing in plaster walls.

** Optional tools to make the installation easier.

3) Speaker Location

To achieve the best performance from your Dayton Audio speakers, it is important to carefully

select the location for installation. Your ceiling speakers should be installed 5 to 8 feet apart to

ensure proper stereo imaging. Mount each speaker the same distance from the intersecting

walls to maintain a uniform look. Keep the speakers at least 2 feet away from the corners of

the room to avoid overemphasized bass reproduction.

4) Speaker Installation

Once you have selected the location for your speakers, you are ready to install them.

CAUTION: Be certain that there are no electrical wires, water pipes, or heating ducts

in the planned installation area before you start drilling or cutting into the ceiling. If

there is an electrical outlet nearby, turn off the circuit breaker to avoid possible injury.

Ceiling speakers are designed to be mounted in the ceiling between the joists or trusses.

Once you have selected the location, check to be sure you are between the joists or truss.

One method is to tap on the ceiling, you will hear a hollow sound when between two joists or

trusses and a sharper, more solid sound when right on top of, or close to a joist or truss.

An easier, more accurate method for finding the location of joists or trusses is to use a

stud finder.

The Contractor Series Ceiling speakers include a two-part template. Remove the center circle

from the template, this is a paint masking template to use if you choose to paint the speaker

frames and grill. The outer ring is used to mark the cut-out for the speakers.

Once you have established that your chosen location is between two joists or trusses, and

that there are no obstructions in the ceiling, tape your speaker template to the ceiling and

lightly trace around the inside edge with a pencil and drill a 1" hole in the center of the

template outline. Next, use a piece of stiff wire (a coat hanger works well), bend it 8" from the

end at a 90 degree angle. Insert the bent part of the coat hanger into the 1" hole and rotate

the wire in a complete circle to check for obstructions. If the wire hits a stud on either side,

reposition your template to the left or right and mark the outline again. Keep the pilot hole

within the template outline.

If the ceiling is made of drywall, simply cut the marked area with your utility knife or drywall

saw. If the ceiling is made of plaster, you should use a saw with a higher tooth count to re-