10

making solder joints to connectors. Where possible it is

recommended to fit crimped brass sleeves to the conductors

and then solder the sleeve to the connector. If direct solder

connections have to be made, use a high-temperature solder-

pot to tin the tinsel conductors before making the solder joint

to the connector, but be careful that the nylon thread does not

melt. Direct solder connections can be made to all other cables

with free ends (for cable connection refer to “Wiring Diagram”

pages 14-15). On request, the necessary plugs can be mounted

at the factory.

Operation

The DT 150 and DT 190 are of a professional standard. It

is important that the external equipment they will be connec

ted

to are of good quality and of the correct impedance and power

ratings to get the best performance from them. Please refer to

the „Technical Specifications“ for detailed information.

The headphone is fully adjustable and should be positioned for

the best fit over the ears. This will give maximum long-term

comfort and will minimise sound leakage or spill.

Convention states that with the DT 190 the boom is placed over

the left ear and the earphones of the DT 190 are identified: L

and R (left and right). The microphone can be used from the

right ear, but if true L and R status should be maintained, or

split feeds are in operation, it may be necessary to make a

custom lead with the headphone connections reversed. The

L&R nomenclature plates of the DT 190 can also be swapped to

reflect these changes.

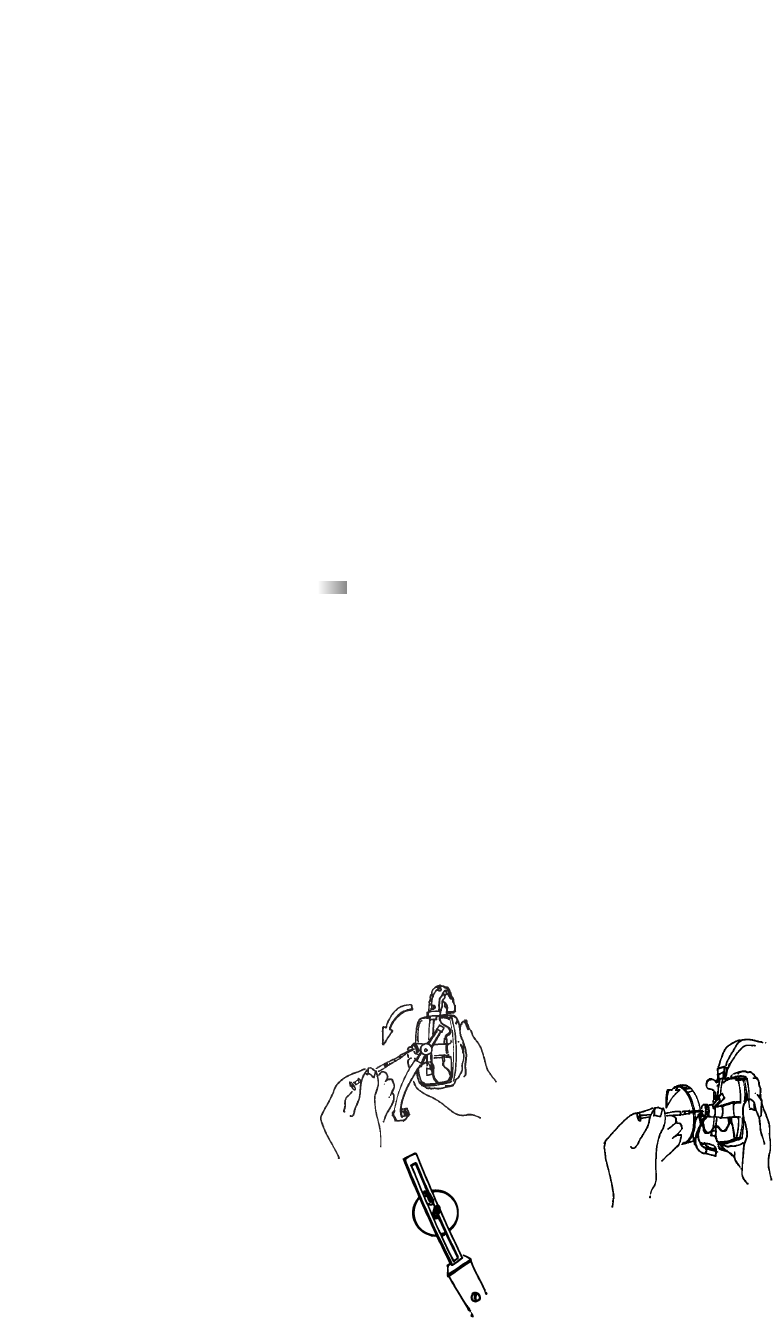

DT 190

1. Lift cap with small screwdriver.

2. Loosen flat screw.

3. Turn disc 180°. Nose of the disc

points to the upper end of the boom

arm.

4. Tighten flat screw and put cap on turning knob.