15

TUBE ULTRAGAIN T1953

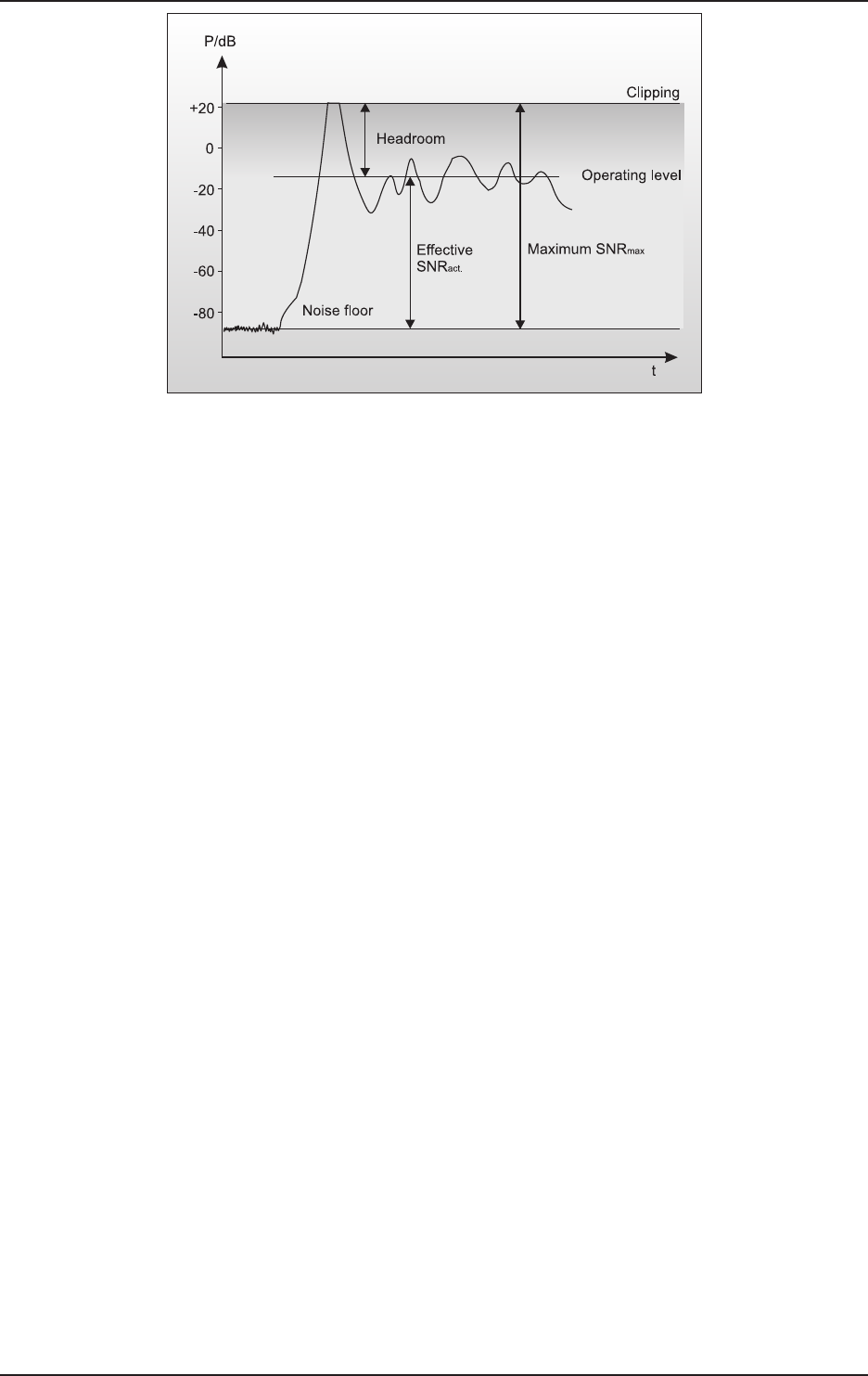

Fig. 4.3: The interactive relationship between operating level and headroom

The need therefore arises for a fast acting automatic gain control system which will constantly monitor the

signals and which will always adjust the gain to maximize the signal-to-noise ratio without incurring signal

distortion. This device is called a compressor or limiter.

4.2 The tubes used in the TUBEULTRAGAIN

A closer look at developments and trends in audio technology shows that tubes are currently enjoying a

renaissance, in a time when even amateur musicians are free to use digital effects processors and recording

media, and ever more affordable digital mixing consoles are becoming a natural part of the equipment of many

semi-professional studios. The manufacturers try with ever new algorithms to get the most out of DSPs (Digital

Signal Processors), the heart of any digital system.

Still, many audio engineers, particularly old hands often prefer using both old and new tube-equipped devices.

As they want to use their warm sound character for their productions, they are ready to accept that these

goodies produce a higher noise floor than modern, transistor-based devices. As a consequence, you can find

a variety of tube-based microphones, equalizers, preamps and compressors in todays recording and

mastering environments. The combination of semiconductor and tube technologies gives you the additional

possibility of using the best of both worlds, while being able to make up for their specific drawbacks.

4.3 Tube history

Due to many patent litigations, it is difficult to determine exactly when the tube was born. First developments

in tube technology were reported between 1904 and 1906. It was a research task of that time to find a suitable

method for receiving and rectifying high frequencies. On April 12, 1905, a certain Mr. Fleming was granted a

patent for his hot-cathode valve which was based on Edisons incandescent lamp. This valve was used as a

rectifier for high-frequency signals. Robert van Lieben was the first to discover (probably by chance) that the

anode current can be controlled by means of a perforated metal plate (grid), one of the milestones in the

development of amplification tubes. In 1912, Robert van Lieben finally developed the first tube for the

amplification of low-frequency signals. Initially, the biggest problem was to produce sufficient volume levels,

which is why resonance step-ups (though impairing the frequency response) were used to maximize the

attainable volume. Later, the objective was to optimize the electroacoustic transducers of amplifiers in such a

way that a broad frequency band could be transmitted with the least distortion possible. However, a tube-

specific problem is its non-linear amplification curve, i.e. it modifies the sound character of the source material.

Despite all efforts to ensure a largely linear frequency response, it had to be accepted that tube devices

produce a bad sound. Additionally, the noise floor generated by the tubes limited the usable dynamics of

connected storage media (magnetic tape machines). Thus, a one-to-one reproduction of the audio signals

dynamics (expressed as the difference between the highest and lowest loudness levels of the program

material) proved impossible. To top it all, tube devices required the use of high-quality and often costly

transducers and sophisticated voltage supplies.

4. TECHNICAL BACKGROUND