DL18MT

Low-Frequency

Reproducer

General Product Description

The DL18MT low-frequency reproducer is a 460 mm (18-inch), 8-ohm

driver designed for professional high-level, high-fidelity monitoring and

sound reinforcement. At the heart of this speaker is a carefully

engineered drive system. Its design assures linear, low distortion output,

high power capability and efficient heat transfer.

Incorporated into the design are three exclusive Electro-Voice

®

innovations. PROTEF™ coating (U.S. patent #4,547,632), a Teflon

®

-based coating, is applied to the inside diameter of the top plate.

Occasional violent power peaks of several seconds may expand a

transducer’s voice coil into contact with the top plate, causing failure.

PROTEF™ proides protection against such failure. The coating

lubricates any rubbing contact and provides electrical insulation between

the coil and the steel top plate. The Thermo Inductive Ring (TIR™) and

Flux Demodulation Device (FDD™), also included in the DL18MT

design, are aluminum castings fastened to the pole of the magnet. They

provided a shorted turn to control inductance and provide a major heat

transfer path from the voice coil, which improves power handling and

reduces thermal, dynamic-range compression.

The voice coil itself is constructed of edge-wound rectangular copper

wire, mounted on a rugged laminated polyimide former. The complete

assembly is fabricated using the most advanced epoxies, insulations

and materials available.

Great care was taken in the selection of diaphragm materials and

construction to ensure smooth, musical upper-bass reproduction and

accurate low-frequency shock capability (punch). The cone has a

moisture-repellent treatment, allowing it to be used in harsh and humid

conditions. (Do not expose the cone to direct water or sunlight.)

The DL18MT is a true high-fidelity woofer in every sense, being capable

of high output, low distortion and solid bass response.

Architects’ and Engineers’ Specifications

The low-frequency woofer shall have a nominal diameter of 457 mm

(18.0 in.), an overall depth of 188 mm (7.42 in.) and weigh less than 9.3

kg (20.5 lb). The frame shall be constructed of strong,

deformation-resistant die-cast aluminum. The magnet assembly shall

incorporate PROTEF™ protection, a TIR™ (Thermo Inductive Ring)

and FDD™ (Flux Demodulation Device) to reduce inductive coupling

and increase power handling. The cone and dust dome should withstand

use in damp and humid conditions. The voice coil shall have a diameter

of 64 mm (2.5 in.), a winding depth of 20.3 mm (0.8 in.) and be made of

edge-wound copper ribbon. The voice-coil former shall be made of

aerospace-grade polyimide laminate and bonded with high-temperature

epoxy adhesives. The performance specification of a representative

production unit shall be as follows: measured sensitivity (SPL at 1 m

(3.3 ft) with 1 watt input, 100- to 800-Hz pink noise) shall be in excess

of 95 dB. The halfspace reference efficiency shall be at least 2.9%. The

usable response shall be 30 to 3,000 Hz, and the nominal impedance

shall be 8 ohms. The EIA rated power shall be 400 watts. The

low-frequency transducer shall be the Electro-Voice DL18MT.

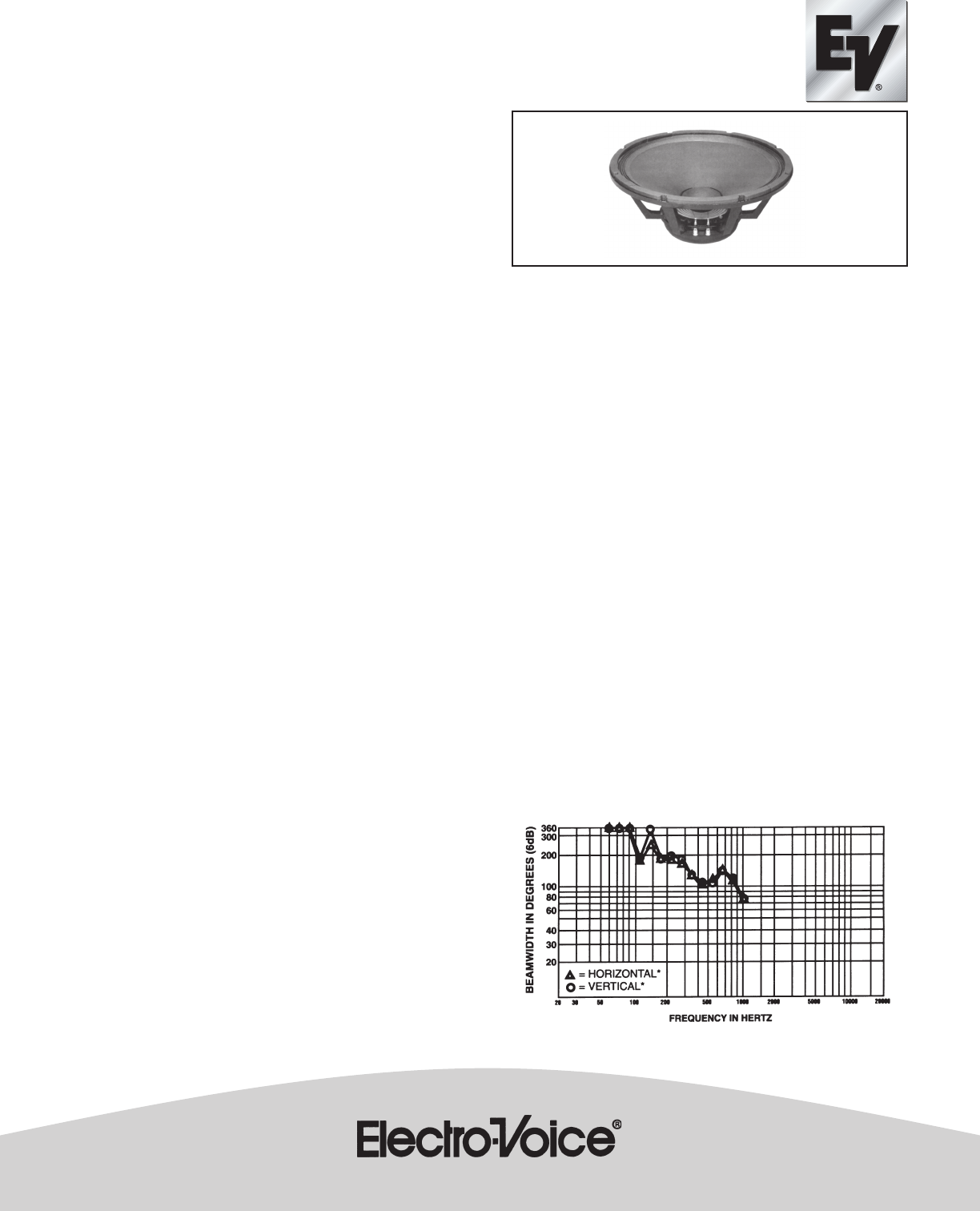

Directional Characteristics

The directional characteristics of the DL18MT in the 7.4-cubic-foot

TL18-1 vented enclosure were measured in ElectroVoice’s large

anechoic chamber. The test signal was one-third-octave filtered pink

noise centered at the frequencies indicated. All directional information

was measured at 20 feet. Figure 1 shows the horizontal and vertical

beamwidths. Beamwidth is the angle at which the horizontal and vertical

polar responses have decreased in level by 6 dB when compared to

the axial frequency response. Figure 2 illustrates the total directivity of

the DL18MT. The directivity factor R

q

(Q) is the relative value, at a point,

of the DL18MT when compared to an ideal spherical response. The

directivity index, D

i

, is calculated by the formula: D

i

= 10 log

10

R

q

.

Electrical Connections

The DL18MT is fitted with a pair of plated, frame-mounted connectors

with color-coded ends. Electrical connection is made by pushing down,

inserting wire completely through the rectangular slot and releasing

pressure. One conductor of #9 stranded, #8 AWG solid, a pair of twisted

#15 AWG stranded or a pair of #14 AWG solid conductors will fit.

Typical Amplifier Size

400-800 watts per woofer is the optimal amplifier size. Amplifiers of this

size will allow maximum output with minimal risk of speaker damage

when properly used. Smaller amplifiers can also be used with excellent

results.

Typical Enclosures

The most extended bass, lowest distortion and best control is usually

realized in properly designed vented enclosures. In such designs, the

vent, or port, actually provides the lowest octave of output. The vent is

driven to full acoustic output by a relatively small motion of the speaker

cone itself, acting through the air contained within the enclosure. The

excursion of the DL18MT at these frequencies is much reduced

compared to sealed or open-back enclosures, directly reducing harmonic

distortion and the possibility of speaker bottoming. Thiele-Small

parameters are provided so designers can tailor the response to suit

their needs.

Normally Tuned Enclosures

A 1.8 cubic-foot enclosure tuned to 55 Hz has a smooth extended

response to below 50 Hz. The 1.1 cubic-foot enclosure “bumps up”

above 70 Hz but has less extended low-bass output.

Figure 1